Corrosion-Resistant NiCr Alloy with High Thermal Conductivity and Precision Electrical Properties

- Product Details

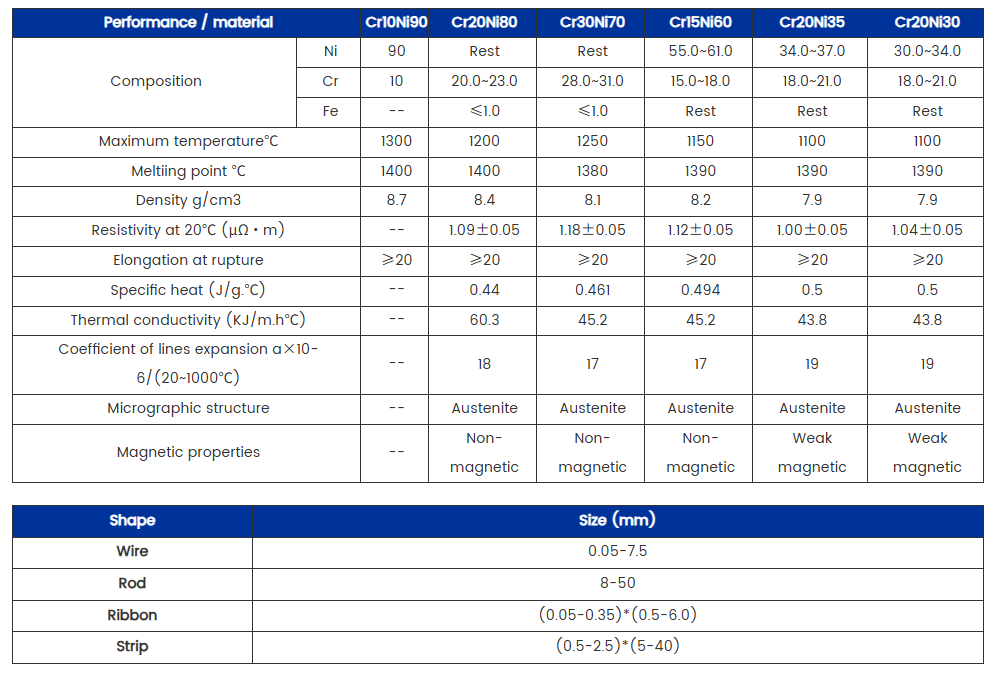

Our corrosion-resistant NiCr alloy, with high thermal conductivity and precision electrical properties, is a powerhouse for manufacturers who need materials that can take the heat—literally and figuratively. Typically composed of 60-80% nickel and 15-20% chromium, this alloy is engineered for demanding applications where reliability, heat dissipation, and electrical precision are non-negotiable.

What sets this NiCr alloy apart? Its high resistivity—around 1.0-1.5 µΩ·m—paired with a low temperature coefficient of resistance (TCR) makes it a rockstar for precision resistors and heating elements. Whether it’s in toasters, industrial furnaces, or high-value rheostats, this alloy delivers consistent electrical performance even when temperatures climb. Speaking of heat, it’s stable up to 1200°C, thanks to a robust chromium oxide layer that protects against oxidation and corrosion in harsh, high-temperature environments.

The thermal conductivity, ranging from 11-17 W/(m·K), is another big win. While it’s not as high as copper, it’s plenty effective for dissipating heat in heating elements, thermocouples, and aerospace turbine components, ensuring systems stay efficient without overheating. Plus, its corrosion resistance is top-notch, especially in oxidizing conditions, making it a go-to for industrial settings where chemical exposure is a concern. Just keep it away from sulfur-heavy atmospheres, where it’s less effective.

Manufacturers love how easy this alloy is to work with. Its good ductility and weldability mean we can form it into wires, strips, or custom shapes without a hassle, perfect for everything from fine thermocouple wires to heavy-duty furnace elements. With a tensile strength of 600-800 MPa and hardness of 180-220 HV, it’s tough enough to handle mechanical stress while staying pliable for precision work.

The nickel-chromium alloy market is thriving, with a growth rate of about 5-6% annually, driven by demand in electrical, aerospace, and automotive sectors. As industries push for more efficient heating systems and reliable electronics, our NiCr alloy’s combination of corrosion resistance, thermal conductivity, and electrical precision makes it a standout. Compared to CuNi 44, it offers higher temperature resistance, and versus FeCrAl alloys, it provides better ductility and corrosion resistance in oxidizing conditions.

We produce this NiCr alloy with rigorous quality controls to ensure consistent resistivity, strength, and surface quality. We’re also committed to sustainability, exploring recycling options to keep our process eco-friendly. While nickel prices can fluctuate, the long lifespan and low maintenance of this alloy make it a cost-effective choice for high-performance applications.

In a nutshell, our NiCr alloy with high thermal conductivity and precision electrical properties is your trusted partner for tackling tough projects. From heating elements to thermocouples, it delivers the durability, efficiency, and reliability you need to keep things running smoothly. Ready to power up your manufacturing? This alloy’s got you covered.

Product Description:

With a specific heat capacity of 460 J/kg.K, our NiCr Alloy can efficiently store and release heat energy, making it an ideal material for thermal management applications. Additionally, it has a tensile strength of 637MPA, which means it can withstand high levels of stress without breaking or deforming.

Our NiCr Alloy has a density of 8.9 G/cm3, making it a relatively lightweight material for its strength and durability. It also has a modulus of elasticity of 200 GPa, which means it can return to its original shape after being bent or stretched.

Overall, our NiCr Alloy product is a reliable and versatile material that can be used in a wide range of applications, including aerospace, automotive, and industrial equipment. Its high-temperature resistance and excellent electrical conductivity make it a popular choice among engineers and manufacturers looking for a durable and efficient material for their projects.

For more details, pls directly contact us.

Applications:

The NiCr Alloy is a versatile product that finds application in a wide range of scenarios. One of its primary uses is in the production of heating elements for industrial and household appliances. The alloy's high melting point and excellent corrosion resistance make it ideal for use in ovens, toasters, hair dryers, and other heating appliances. It is also used in the production of heating coils for electronic cigarettes.

Another significant application of the NiCr Alloy is in the automotive industry. The alloy's high temperature and pressure resistance make it ideal for use in exhaust systems, catalytic converters, and oxygen sensors. It is also used in the production of spark plugs and other ignition components in automobiles.

The NiCr Alloy is also used in the aerospace industry due to its high strength and corrosion resistance. It is used in the production of turbine blades, exhaust systems, and other high-temperature components in aircraft engines.

The NiCr Alloy is commonly used in the production of resistance wires and heating elements. It is widely used in the production of industrial furnaces, kilns, and other high-temperature applications. The alloy's excellent electrical and thermal conductivity make it ideal for use in resistance heating.

The NiCr Alloy is also used in the production of hot stamping dies and other high-temperature tooling. Its high strength and hardness make it ideal for use in manufacturing processes that require high-temperature resistance and wear resistance. The alloy is also used in the production of corrosion-resistant coatings and other protective coatings.

The NiCr Alloy is an excellent alternative to other alloys such as Nikrothal 40. Its unique properties make it ideal for use in various industries and applications, including the automotive, aerospace, and electronics industries. Whether you need a resistance wire for a heating element or a high-temperature component for an industrial furnace, the NiCr Alloy is a reliable and cost-effective solution.

Support and Services:

Product Technical Support:

- Our knowledgeable technical support team is available to assist with any questions or concerns regarding the NiCr Alloy product.

- We provide detailed product specifications and performance data to ensure proper usage and application.

Product Services:

- We offer customization services to meet specific customer requirements.

- Our product experts can provide recommendations for optimal product usage and maintenance.

- We also offer product training and educational resources to ensure safe and effective use of the NiCr Alloy product.

Packing and Shipping:

Product Packaging:

The NiCr Alloy product will be packed securely in a cardboard box to protect it during shipping. The box will be labeled with the product name, quantity, and any necessary handling instructions.

Shipping:

We offer worldwide shipping for the NiCr Alloy product. Shipping costs will be calculated based on the destination and the weight of the product. We use trusted carriers to ensure safe and timely delivery.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What is a NiCr alloy with high thermal conductivity and precision electrical properties?

It’s a nickel-chromium alloy, typically with 60-80% nickel and 15-20% chromium, designed for high thermal conductivity, precise resistivity (~1.0-1.5 µΩ·m), and corrosion resistance.

What are its primary applications?

It’s used in heating elements (e.g., toasters, ovens), precision resistors, thermocouples, and industrial furnace components due to its electrical stability and heat resistance.

How does its corrosion resistance perform?

NiCr alloys form a stable chromium oxide layer, offering excellent resistance to oxidation and corrosion in high-temperature and chemical environments, including sulfur-free conditions.

What makes its electrical properties precise?

Its high resistivity (~1.0-1.5 µΩ·m) and low temperature coefficient of resistance (TCR) ensure stable performance in precision resistors and heating elements across temperature changes.

How does its thermal conductivity compare?

With thermal conductivity around 11-17 W/(m·K), it’s lower than copper (~400 W/(m·K)) but sufficient for heat dissipation in heating elements and industrial applications.

Can it withstand high temperatures?

Yes, it’s stable up to 1200°C (e.g., NiCr 80:20), ideal for high-temperature applications like industrial furnaces and heating appliances.

Which industries rely on this NiCr alloy?

Electrical, aerospace, automotive, and industrial manufacturing use it for resistors, heating elements, thermocouples, and turbine components.

Is it easy to process for manufacturing?

Its good ductility and weldability make it easy to form, draw, and weld into wires, strips, or custom components for various applications.

-

Hot Sale OEM Melting Range From 1320°C To 1370 °C Nichrome Alloy Bar Material

Enquire Now -

New Hot Nickel Aluminum Bronze Bar Nickel Alloy B3 Round Bar/Rod For Sale

Enquire Now -

Cold Drawing Treatment Copper Bar And Copper Alloys with Ni-Cr Conductor Material

Enquire Now -

NiCr Alloy Bar NCHW-1 State Hard Trade Term EXW for Industrial Applications

Enquire Now