Hot Sale OEM Melting Range From 1320°C To 1370 °C Nichrome Alloy Bar Material

- Product Details

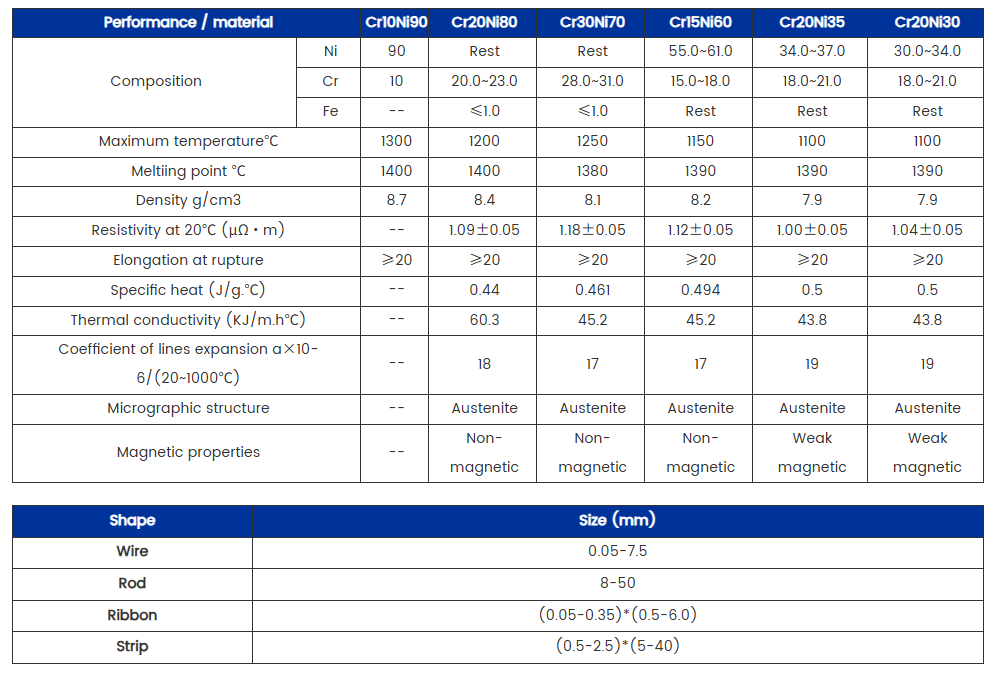

Our Nichrome alloy bar, with a melting range of 1320-1370°C, is a top seller for OEMs who need a material that can handle extreme heat and deliver precise performance. Made with 60-80% nickel and 15-20% chromium, this alloy is a workhorse for high-temperature applications, offering the perfect blend of oxidation resistance, electrical precision, and mechanical strength.

This bar’s high resistivity—around 1.0-1.5 µΩ·m—makes it ideal for heating elements and precision resistors. Whether it’s powering industrial furnaces, toasters, or electric ovens, its low temperature coefficient of resistance (~100 ppm/°C) ensures stable performance even when things get hot. Speaking of heat, it thrives at temperatures up to 1200°C, thanks to a tough chromium oxide layer that protects against oxidation and corrosion in oxidizing environments. Just steer clear of sulfur-heavy settings, where it’s less effective.

With a tensile strength of 600-800 MPa and hardness of 180-220 HV, this Nichrome bar is built to last under mechanical stress, resisting creep even at high temperatures. Its ductility and weldability are a big plus for OEMs, letting us customize it into specific bar sizes or shapes for applications like aerospace turbine components or automotive resistors. The thermal conductivity (11-17 W/m·K) is solid for heat dissipation, keeping systems efficient in demanding setups.

Product Description:

The NiCr Alloy is available in two treatment options: annealed and cold drawing. Annealing is a heat treatment process that improves the ductility and toughness of the alloy while cold drawing increases its strength and hardness. The choice of treatment depends on the specific application and required properties of the alloy.

The melting range of the NiCr Alloy is between 1320-1370 °C, and it can be cast into various shapes such as rods, wires, and sheets. The alloy's high temperature resistance makes it ideal for use in applications where high temperature and corrosion resistance are required.

The NiCr Alloy is commonly used in the production of heating elements, furnaces, and industrial ovens. The high nickel content in the alloy gives it excellent resistance to oxidation and corrosion, making it suitable for use in harsh environments. The alloy's excellent mechanical properties, including high strength and ductility, make it ideal for use in the manufacture of components that must withstand high stress and pressure.

The NiCr Alloy is available on different trade terms, including FOB, EXW, and CIF, making it accessible to customers worldwide. Customers can choose the trade term that best suits their needs and budget.

In summary, the NiCr Alloy is a high temperature resistance alloy that is used in various industries where high temperature and corrosion resistance are required. It is available in different grades and treatment options and can be cast into various shapes. Its excellent mechanical and chemical properties make it ideal for use in the manufacture of components that must withstand harsh environments. With different trade terms, the NiCr Alloy is accessible to customers worldwide.

For more details, pls directly contact us.

Applications:

One of the most common applications of DLX NiCr Alloy is in the production of heating elements. The high melting range and excellent resistance to oxidation make it an ideal material for heating elements that operate at high temperatures. The product is also used in the manufacturing of electrical resistance wires, which are used in a variety of electrical applications.

Another important application of DLX NiCr Alloy is in the aerospace industry. The product is used in the production of aircraft engines and gas turbine components due to its high strength and resistance to corrosion. It is also commonly used in the manufacturing of heat exchangers, which are used in aircraft and spacecraft to regulate temperature.

DLX NiCr Alloy is also used in the automotive industry. It is used in the manufacturing of exhaust systems and catalytic converters due to its high-temperature resistance and corrosion resistance. The product is also used in the production of spark plug electrodes.

DLX NiCr Alloy is also used in the production of Aluminium Copper Alloy, Copper Alloy Plate, and Copper Clad Steel. The product is used as a coating material due to its resistance to corrosion and high-temperature resistance. It is also used in the manufacturing of electrodes and heating elements for welding applications.

In conclusion, DLX NiCr Alloy is a versatile product that has a wide range of applications in various industries. Its unique properties, such as high strength, resistance to corrosion, and high-temperature resistance, make it an ideal material for various applications. Whether it is used in the production of heating elements, aircraft engines, or automotive exhaust systems, DLX NiCr Alloy is sure to deliver excellent performance.

Customization:

DLX offers product customization services for NiCr Alloy, a type of alloy steel metal that contains nickel and chromium. This product is available in grade Ni60Cr23/Inconel601/UNS N06601/610H and can be traced back to its place of origin in China. The leading time for this product ranges from 5 to 20 days, depending on the order quantity. The nickel content of this product varies according to the material used. Its elongation rate ranges from 20-30%. Samples of this product are available for free.

DLX also specializes in copper and copper alloys, offering a wide range of customization options and high-quality products.

Support and Services:

Our NiCr Alloy product comes with comprehensive technical support and services to ensure optimal performance and longevity. Our team of experts is available to provide technical assistance and advice on the selection, installation, and maintenance of our NiCr Alloy products.

We also offer a range of services to support our customers, including product testing, inspection, and analysis. Our state-of-the-art facilities and equipment allow us to provide accurate and reliable testing results to help our customers optimize their production processes.

In addition, we offer training and education programs to help our customers improve their knowledge and skills in working with NiCr Alloy products. These programs cover a range of topics, including product handling, safety, and troubleshooting.

Overall, our commitment to providing exceptional technical support and services ensures that our customers can rely on our NiCr Alloy products for their critical applications.

Packing and Shipping:

Product packaging:

The NiCr Alloy product will be securely packaged in a sturdy cardboard box.

The product will be wrapped in bubble wrap to prevent any damage during shipping.

Each package will include a label with the product name, quantity, and any warnings or handling instructions.

Shipping:

Shipping will be handled by a reputable carrier, such as FedEx or UPS.

Orders will be processed and shipped within 1-2 business days of receipt.

Customers will receive a tracking number once their order has shipped, so they can track their package's progress.

Please note that shipping times may vary depending on the destination and carrier used.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What is the Nichrome alloy bar with a 1320-1370°C melting range?

It’s a nickel-chromium alloy bar, typically with 60-80% nickel and 15-20% chromium, known for high resistivity (~1.0-1.5 µΩ·m), oxidation resistance, and a melting range of 1320-1370°C.What are its primary applications?

It’s used in industrial furnaces, heating elements (e.g., toasters, ovens), resistors, and aerospace components due to its high-temperature stability and electrical properties.How does its corrosion resistance perform?

It forms a stable chromium oxide layer, providing excellent resistance to oxidation and corrosion in high-temperature and oxidizing environments, though less effective in sulfur-rich conditions.What makes its electrical properties suitable for heating?

Its high resistivity (~1.0-1.5 µΩ·m) and low temperature coefficient of resistance (TCR ~100 ppm/°C) ensure stable performance in precision resistors and heating elements.Can it withstand extreme temperatures?

Yes, it operates reliably up to 1200°C, with a melting range of 1320-1370°C, making it ideal for high-temperature applications like furnace elements.How does it compare to other high-temperature alloys?

Compared to FeCrAl alloys (melting ~1400-1500°C), it has better ductility and corrosion resistance in oxidizing environments but lower maximum temperature tolerance.Which industries use this Nichrome bar?

Electrical, aerospace, automotive, and industrial manufacturing rely on it for heating elements, resistors, and turbine components.Is it suitable for OEM customization?

Yes, its good ductility and weldability allow easy forming and machining into custom bar sizes and shapes for OEM needs.

-

Corrosion-Resistant NiCr Alloy with High Thermal Conductivity and Precision Electrical Properties

Enquire Now -

New Hot Nickel Aluminum Bronze Bar Nickel Alloy B3 Round Bar/Rod For Sale

Enquire Now -

Cold Drawing Treatment Copper Bar And Copper Alloys with Ni-Cr Conductor Material

Enquire Now -

NiCr Alloy Bar NCHW-1 State Hard Trade Term EXW for Industrial Applications

Enquire Now