8.94 G/cm3 CuNi Alloy NC005(CuNi2) with High Tensile Strength and Hardness

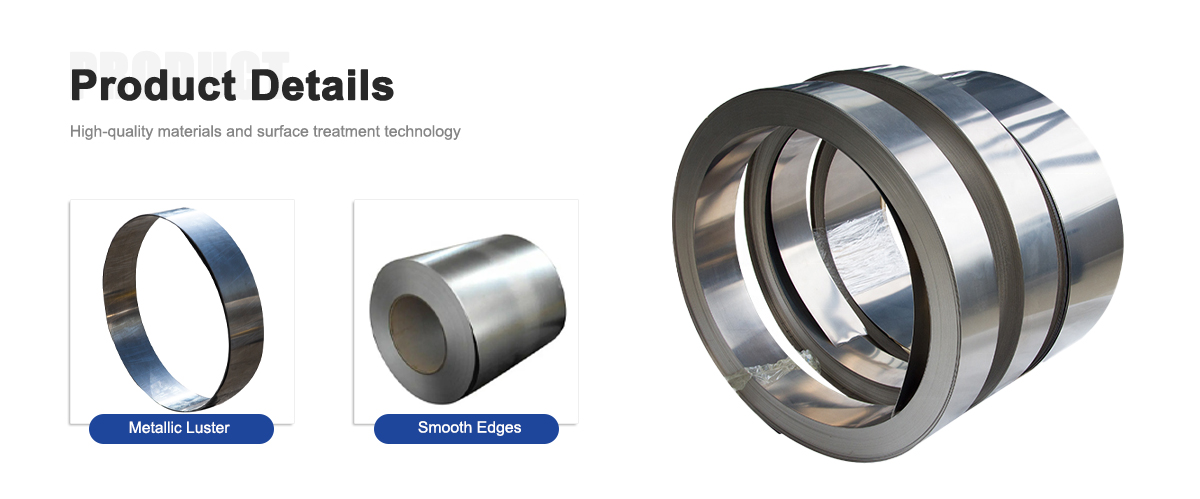

- Product Details

Our CuNi Alloy NC005, or CuNi2, with a density of 8.94 g/cm³, is a total standout for projects needing high tensile strength and hardness without costing a fortune. With just 2% nickel, this copper-heavy alloy packs a punch with its durability, low electrical resistivity, and top-notch corrosion resistance, making it a go-to for industries from electrical to marine.

Let’s dive into what makes CuNi2 so special. Its tensile strength, ranging from 300-450 MPa, and hardness of 80-130 HV make it tough enough for high-stress applications like electrical connectors, springs, and marine fittings. It’s built to last, even in demanding conditions. Plus, with a super-low resistivity of about 0.05-0.1 µΩ·m, it’s a fantastic choice for electrical components like resistors, heating wires, and circuit breakers where efficient current flow is key.

Corrosion resistance is where CuNi2 really shines. It forms a protective oxide layer that stands up to seawater, making it a favorite for marine applications like ship fittings, valves, and piping in desalination plants. It’s also stable up to 250-300°C, which is plenty for low to medium-temperature setups like heating wires or automotive electrical systems. And because it’s highly ductile and weldable, we can easily shape it into custom parts, saving time and hassle in manufacturing.

The copper-nickel alloy market is buzzing, growing at around 5-6% a year, driven by demand in marine, renewable energy, and electronics. With more desalination projects and offshore energy systems coming online, CuNi2’s corrosion resistance and affordability make it a hot commodity. It’s also sneaking into automotive applications, like brake line fittings, because it’s strong yet corrosion-proof compared to steel.

We take pride in producing CuNi2 with strict quality controls to ensure consistent strength, hardness, and resistivity. We’re also exploring sustainable practices, like recycling nickel alloys, to keep our process eco-friendly. While raw material prices can be unpredictable, CuNi2’s long lifespan and low maintenance costs make it a budget-friendly choice for high-performance needs.

In a nutshell, our CuNi Alloy NC005 (CuNi2) is all about strength, reliability, and versatility. Whether you’re building electrical systems, marine hardware, or automotive components, this alloy delivers the durability and efficiency you need at a price that makes sense. It’s no surprise it’s one of our top picks for tackling tough projects.

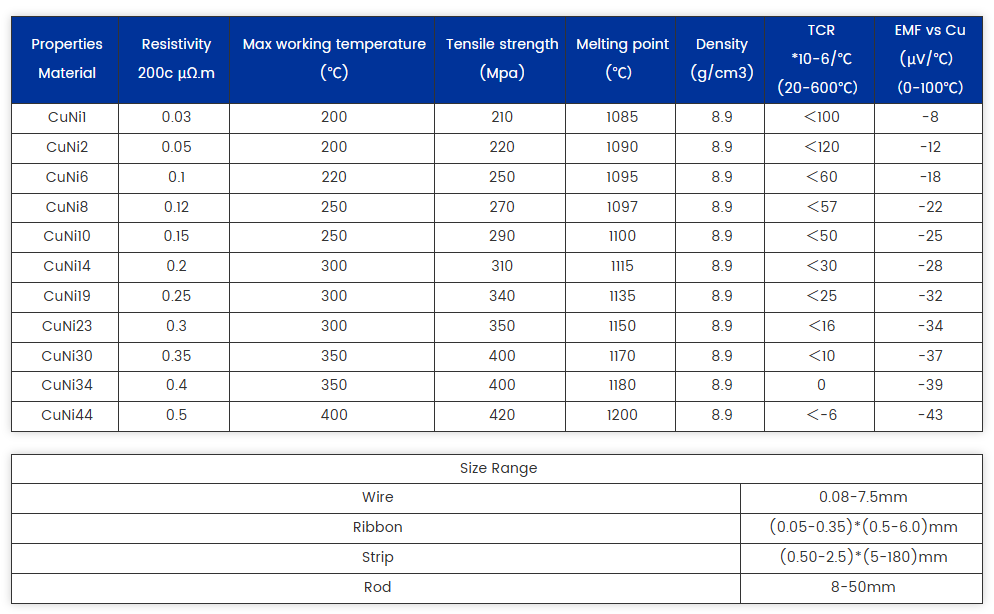

Specification

For more details, pls directly contact us.

Product Description:

One of the key advantages of the CuNi Alloy is its EMF vs Cu rating of -18 UV/C. This makes it an excellent choice for use in environments where resistance to corrosion is paramount. Additionally, this alloy is highly resistant to seawater corrosion, making it an ideal choice for marine applications such as offshore platforms and shipbuilding.

The CuNi Alloy is a type of Copper Metal Product, and is often used in combination with other materials to create alloys for specific applications. One such alloy is the Aluminium Copper Alloy, which is commonly used in the aerospace industry due to its high strength and excellent resistance to corrosion.

The CuNi Alloy is a versatile product that can be used in a variety of applications, including electrical engineering, marine engineering, and chemical engineering. Its high level of resistance to corrosion, coupled with its excellent mechanical properties, make it a reliable and cost-effective choice for many different industries.

Features:

Product Name: CuNi Alloy

Resistivity: 0.5

Hardness: 80-120 HV

Sureface: Bright

Maximum Temperature: 200℃

Diameter: 0.1~10mm

Material Type: Copper Based Alloys, Alloy Steel Metal, Inconel Nickel Alloy

Applications:

The copper and nickel composition of the DLX CuNi Alloy makes it an excellent choice for use in a variety of scenarios. It is widely used in the manufacturing of Copper Metal Products like switches, relays, and connectors, among others. The alloy's unique composition provides excellent electrical conductivity, making it ideal for use in electrical applications.

The DLX CuNi Alloy is available in both hard and soft conditions, making it suitable for use in different applications. The hard condition is ideal for use in applications that require high strength, such as springs and electrical contacts. On the other hand, the soft condition is ideal for use in applications that require high ductility, such as wires and cables.

The surface of the DLX CuNi Alloy is bright, providing a smooth finish that is ideal for use in decorative applications. The bright surface finish also makes it easy to clean and maintain, making it ideal for use in applications where hygiene is essential.

The DLX CuNi Alloy is suitable for use in various product application occasions and scenarios. It is widely used in the automotive, aerospace, and electrical industries, among others. In the automotive industry, the alloy is used in the manufacturing of ignition systems, fuel injectors, and sensors. In the aerospace industry, the alloy is used in the manufacturing of electrical connectors, switches, and relays. In the electrical industry, the alloy is used in the manufacturing of wires, cables, and bus bars.

In conclusion, the DLX CuNi Alloy is an excellent choice for use in various applications due to its unique composition, resistivity, and maximum temperature limit. Its availability in both hard and soft conditions and its bright surface finish make it suitable for use in different scenarios. Its wide application in various industries is a testament to its versatility and reliability as a copper-based alloy product.

Customization:

Our brand, DLX, offers top-notch product customization services for our Copper Based Alloys. Our CuNi Alloy, model number: CuNi Alloy, is a high-quality Copper Nickel Alloy that originates from China. With a maximum temperature capacity of 200℃, our CuNi Alloy is an excellent choice for various industries. Its exceptional corrosion resistance and thermal expansion coefficient of 16.5 X 10^-6/K make it a reliable option for critical applications. Our CuNi Alloy has a bright surface and a density of 8.94 G/cm3. Our Product Customization Services enable you to tailor our Copper Metal Products to your unique requirements.

Support and Services:

Our CuNi Alloy product is backed by our expert technical support and services team. We offer comprehensive product information, installation guidance, and troubleshooting advice to ensure our customers get the most out of our product.

In addition, we offer custom fabrication services to meet specific project needs. Our team of experienced fabricators can work with customers to create custom components and assemblies made from our CuNi Alloy product.

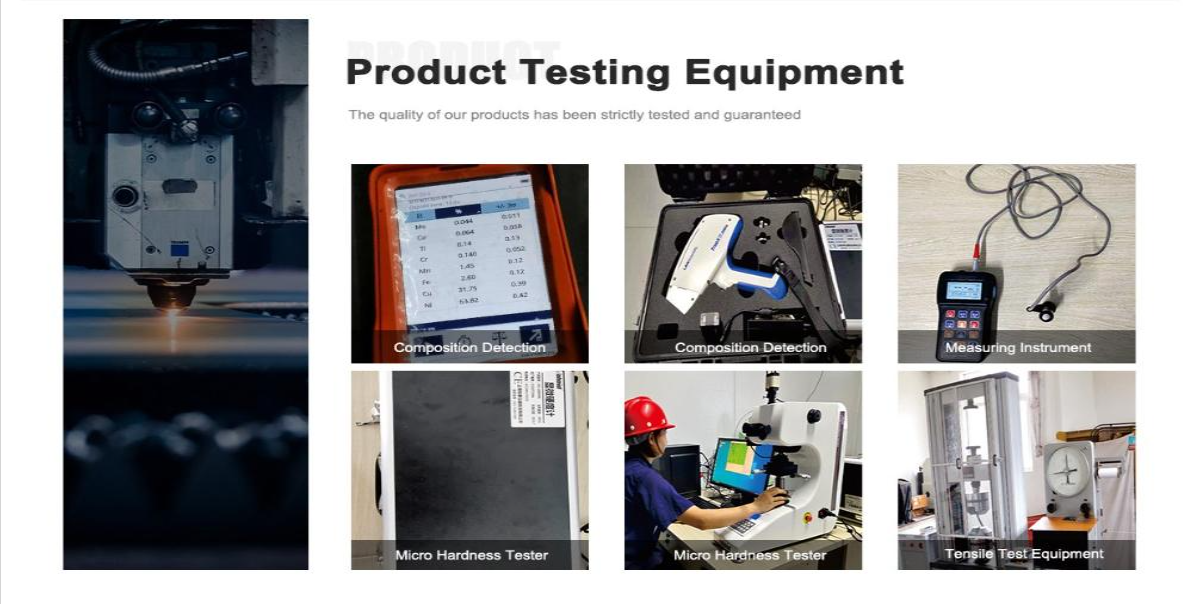

We also provide testing and analysis services to ensure the quality and integrity of our CuNi Alloy product. Our testing services include non-destructive testing, metallurgical analysis, and corrosion testing.

Overall, our commitment to technical support and services ensures that our CuNi Alloy product performs at its best and meets the unique needs of each customer.

Packing and Shipping:

Product Packaging:

The CuNi Alloy product will be packaged in a sturdy cardboard box.

The product will be wrapped in protective material to prevent any damage during shipping.

The box will be labeled with the product name, quantity, and any necessary handling instructions.

Shipping:

The CuNi Alloy product will be shipped via a reputable carrier such as UPS or FedEx.

The product will be insured for its full value during shipping.

Tracking information will be provided to the customer once the product has been shipped.

Shipping costs will be calculated based on the destination and weight of the package.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

What is CuNi Alloy NC005 (CuNi2)?

It’s a copper-nickel alloy with about 2% nickel (Cu98Ni2), known for high tensile strength, hardness, low resistivity, and corrosion resistance, ideal for electrical and marine applications.

What are the main applications for CuNi2?

It’s used in resistors, heating wires, electrical connectors, and marine components like fittings and valves due to its strength and corrosion resistance.

How strong is CuNi2?

It offers a tensile strength of around 300-450 MPa, depending on processing, making it robust for high-stress applications like connectors and springs.

How does it perform in corrosive environments?

CuNi2 has excellent corrosion resistance, especially in seawater, forming a protective oxide layer, perfect for marine hardware and piping.

What’s its electrical resistivity like?

With a resistivity of about 0.05-0.1 µΩ·m, it’s highly conductive, ideal for low-resistance electrical components compared to higher-nickel alloys.

Can CuNi2 withstand high temperatures?

It’s stable up to about 250-300°C, suitable for low to medium-temperature applications like heating wires and electrical fittings.

Which industries use CuNi2?

Electrical, marine, automotive, and renewable energy sectors rely on it for its durability, conductivity, and cost-effectiveness.

Is CuNi2 easy to process?

Yes, its good ductility and weldability make it easy to form and join, ideal for manufacturing complex parts like connectors and terminals.

-

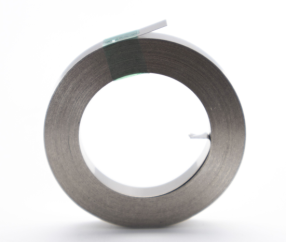

Cheap Price 8.9g/cm3 Hardness Range of 80-120HV With Low Resistivity CuNi Alloy Strip

Enquire Now -

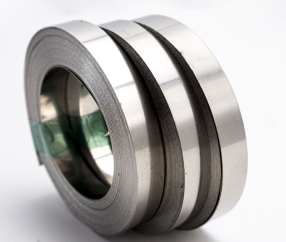

Low Resistivity With High Temperature Customized CuNi Alloy Strip For Sale

Enquire Now -

CuNi Alloy NC010(CuNi6)The Optimal Solution for High-Temperature and High-Pressure Applications

Enquire Now -

Upgrade Your Manufacturing Process with CuNi Alloy NC003(CuNi1)

Enquire Now