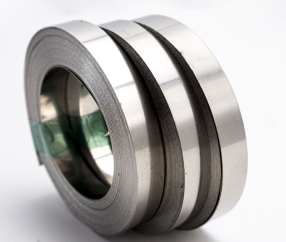

Upgrade Your Manufacturing Process with CuNi Alloy NC003(CuNi1)

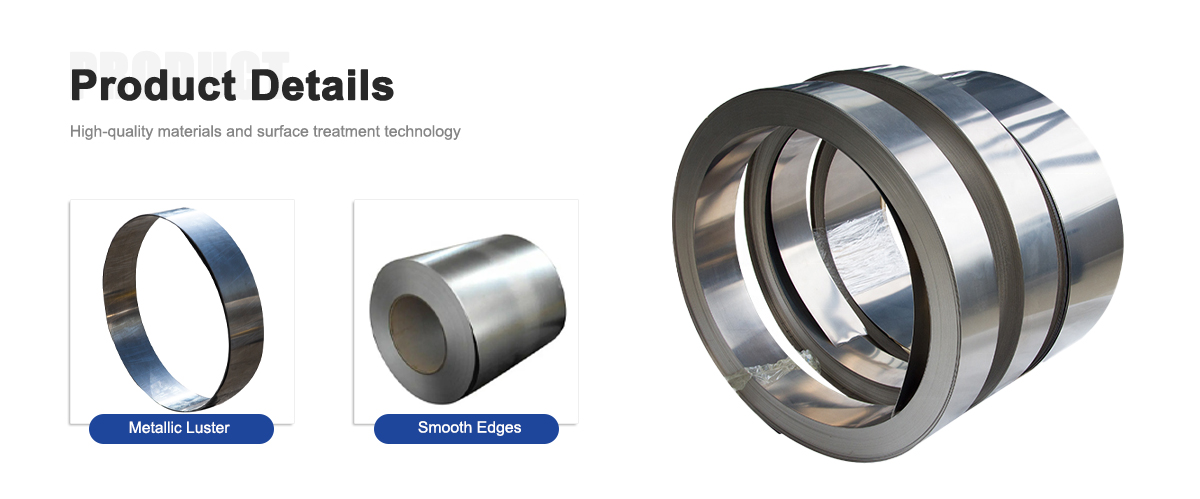

- Product Details

Our CuNi Alloy NC003, or CuNi1, is here to supercharge your manufacturing process with its unbeatable mix of performance and affordability. With just 1% nickel, this copper-heavy alloy delivers ultra-low electrical resistivity, stellar corrosion resistance, and the flexibility to fit into a wide range of applications, from electrical wiring to marine hardware.

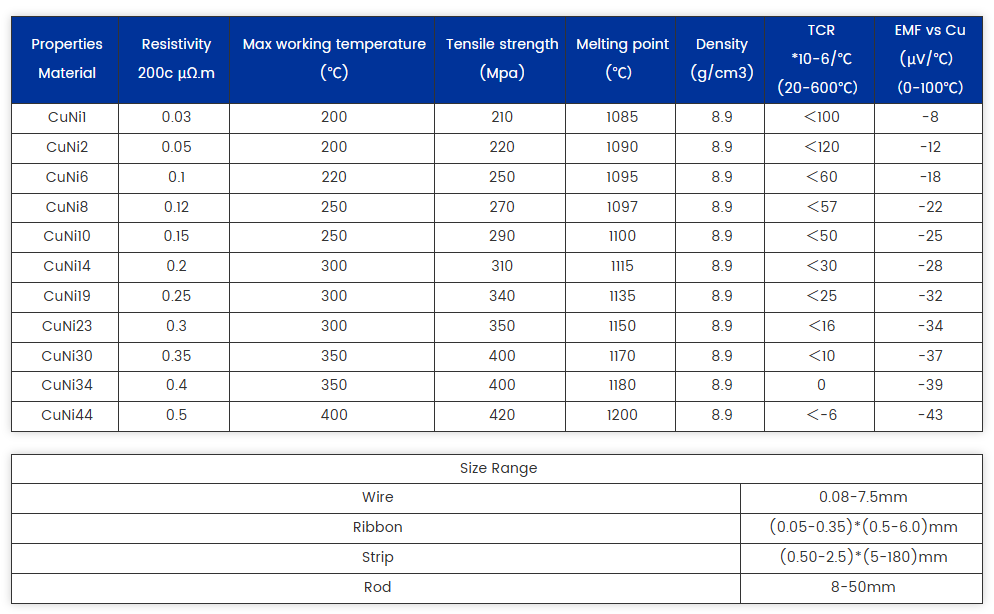

Let’s break it down. CuNi1’s resistivity, clocking in at about 0.03-0.08 µΩ·m, is among the lowest in the copper-nickel family, making it a rockstar for high-conductivity applications. Think electrical connectors, wiring, and low-resistance resistors that keep current flowing efficiently without overheating. It’s also a champ in corrosive environments, especially seawater, thanks to its protective oxide layer. That’s why it’s a go-to for marine fittings, valves, and piping in desalination plants or shipbuilding.

CuNi1’s high ductility is a manufacturer’s dream. It’s easy to form, bend, and weld into custom shapes, whether you’re crafting intricate electrical components or robust marine parts. With a tensile strength of 280-400 MPa and hardness of 70-120 HV, it’s tough enough for demanding applications but still pliable for precision work. It’s stable up to 200-250°C, perfect for low-temperature heating applications like cables or automotive electrical systems.

The copper-nickel alloy market is on fire, growing at about 5-6% annually, driven by demand in marine, electrical, and renewable energy sectors. With global pushes for desalination, offshore wind farms, and advanced electronics, CuNi1’s affordability and performance make it a standout. Its lower nickel content compared to alloys like CuNi6 or CuNi10 keeps costs down while delivering top-tier conductivity, making it a smart pick for budget-conscious projects.

We’re all about quality and sustainability. Our CuNi1 is produced with tight controls to ensure consistent resistivity, strength, and formability. We’re also exploring greener production methods, like recycling nickel alloys, to stay eco-friendly. While raw material prices can fluctuate, CuNi1’s long lifespan and low maintenance needs make it a cost-effective choice for manufacturers looking to optimize without sacrificing quality.

In short, our CuNi Alloy NC003 (CuNi1) is your ticket to upgrading your manufacturing process. Its high conductivity, corrosion resistance, and ease of fabrication make it perfect for electrical, marine, and automotive applications. Ready to streamline your production and boost performance? This alloy’s got you covered with reliability and value that’s hard to beat.

Specification

For more details, pls directly contact us.

Product Description:

With a density of 8.94 G/cm3 and a diameter range of 0.1~10mm, our CuNi Alloy is the perfect choice for a wide range of applications. Whether you're looking for an Aluminium Copper Alloy for high-performance electronics or a Copper Alloy Tube for plumbing and HVAC systems, our product is the perfect fit.

Made from a blend of copper and nickel, our CuNi Alloy is designed to provide superior performance in a variety of environments. With its bright surface and excellent thermal expansion coefficient of 16.5 X 10^-6/K, this product is the ideal choice for any application where high-quality Copper Metal Products are required.

So why wait? Contact us today to learn more about our CuNi Alloy product and how it can help you achieve your goals.

Features:

Product Name: CuNi Alloy

Inconel Nickel Alloy

Copper Based Alloys

Maximum Temperature: 200℃

Condition: Hard / Soft

Corrosion Resistance: Excellent

Surface: Bright

Thermal Expansion Coefficient: 16.5 X 10 -6 /K

Applications:

The CuNi Alloy has excellent corrosion resistance which makes it ideal for use in marine environments, as well as in chemical and petrochemical industries. It can withstand high temperatures up to 200℃, which makes it useful for high-temperature applications.

The surface of DLX's CuNi Alloy is bright and smooth, which makes it aesthetically pleasing and ideal for decorative purposes as well.

The CuNi Alloy is widely used in various industries such as the shipbuilding industry, offshore oil and gas industry, power generation industry, and heat exchanger industry. It is commonly used for making pipes, valves, fittings, and heat exchangers. Due to its excellent corrosion resistance, it is an ideal material for use in seawater applications.

Another important attribute of the CuNi Alloy is its low EMF (electromotive force) compared to copper. It has an EMF vs Cu of -18 UV/C, which makes it suitable for use in electrical and electronic applications.

In summary, DLX's CuNi Alloy is a high-quality copper metal product that is suitable for a wide range of applications. Its excellent corrosion resistance, high-temperature tolerance, and bright surface make it an ideal material for use in various industries.

Customization:

Looking for customized Copper Nickel Alloy products? Look no further than DLX's CuNi Alloy. Our products are made using Copper Powder Metallurgy and Aluminium Copper Alloy, ensuring high-quality and durability. Our CuNi Alloy is made in China and boasts a Tensile Strength of 400-600 MPa, a Bright surface, a Diameter of 0.1~10mm, and a Hardness of 80-120 HV. Additionally, our product has Excellent Corrosion Resistance, making it a reliable choice for any project. Contact us today to learn more about our Product Customization Services.

Support and Services:

Our CuNi alloy product is backed by a comprehensive technical support and services team, dedicated to providing our customers with the following:

Expert technical advice and consultation on product selection, application, and maintenance

Customized product design and engineering services to meet specific project requirements

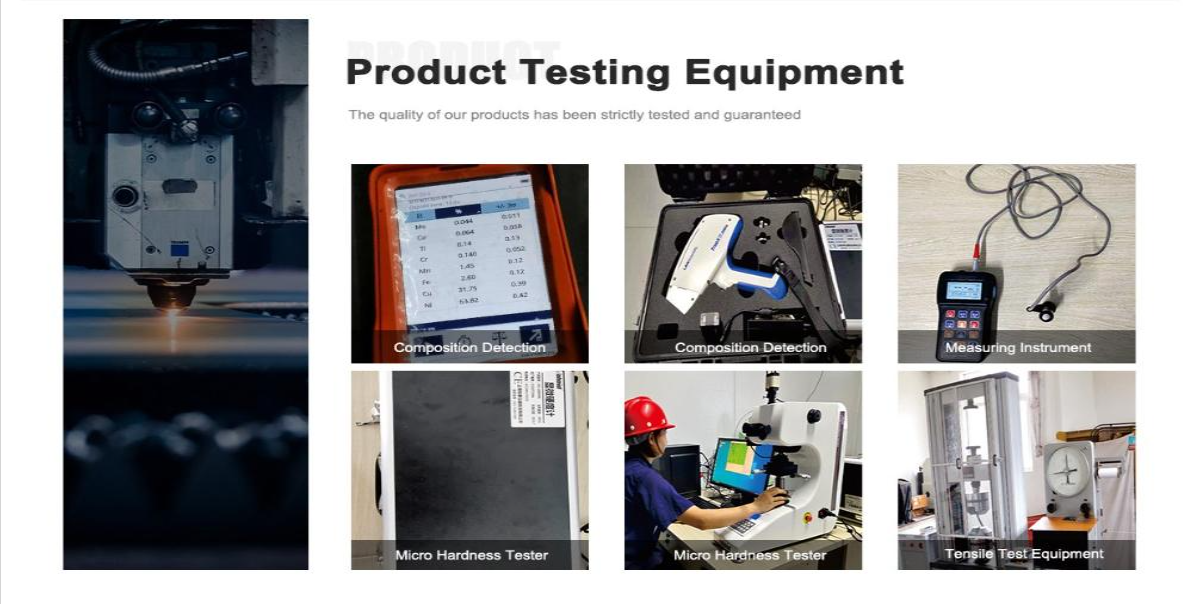

Quality control and testing services to ensure product performance and reliability

Product training and education for customers and their teams on proper handling, installation, and operation

24/7 customer service and support for technical issues and emergencies

We strive to deliver the highest level of support and services to ensure our customers' success with our CuNi alloy product.

Packing and Shipping:

Product Name: CuNi Alloy

Description: A copper-nickel alloy with high resistance to corrosion and oxidation, commonly used in marine applications.

Packaging: The CuNi Alloy product will be carefully packaged in a sturdy wooden crate to ensure safe transport and delivery.

Shipping: We offer both domestic and international shipping options for our CuNi Alloy product. Shipping rates will vary based on the destination and weight of the shipment. Please contact us for a shipping quote.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

What is CuNi Alloy NC003 (CuNi1)?

It’s a copper-nickel alloy with approximately 1% nickel (Cu99Ni1), known for its very low electrical resistivity, corrosion resistance, and ductility, ideal for electrical and marine applications.What are the primary applications for CuNi1?

It’s used in electrical connectors, heating wires, resistors, and marine fittings due to its high conductivity and corrosion resistance.How does CuNi1 perform in corrosive environments?

CuNi1 offers excellent corrosion resistance, forming a protective oxide layer in seawater, making it ideal for marine components like valves and piping.What’s its electrical resistivity like?

With a resistivity of about 0.03-0.08 µΩ·m, it’s one of the lowest among CuNi alloys, perfect for high-conductivity applications like electrical wiring.Is CuNi1 suitable for high-temperature applications?

It’s stable up to around 200-250°C, suitable for low-temperature heating applications like electrical fittings and heating cables.How does CuNi1 compare to other CuNi alloys?

Compared to CuNi6 or CuNi10, CuNi1 has lower nickel content, offering higher conductivity but slightly less strength and temperature resistance.Which industries benefit most from CuNi1?

Electrical, marine, automotive, and telecommunications industries use it for its conductivity, corrosion resistance, and affordability.Is CuNi1 easy to manufacture with?

Yes, its high ductility and excellent weldability make it easy to form and join, streamlining manufacturing processes for complex components.

-

Cheap Price 8.9g/cm3 Hardness Range of 80-120HV With Low Resistivity CuNi Alloy Strip

Enquire Now -

Low Resistivity With High Temperature Customized CuNi Alloy Strip For Sale

Enquire Now -

CuNi Alloy NC010(CuNi6)The Optimal Solution for High-Temperature and High-Pressure Applications

Enquire Now -

8.94 G/cm3 CuNi Alloy NC005(CuNi2) with High Tensile Strength and Hardness

Enquire Now