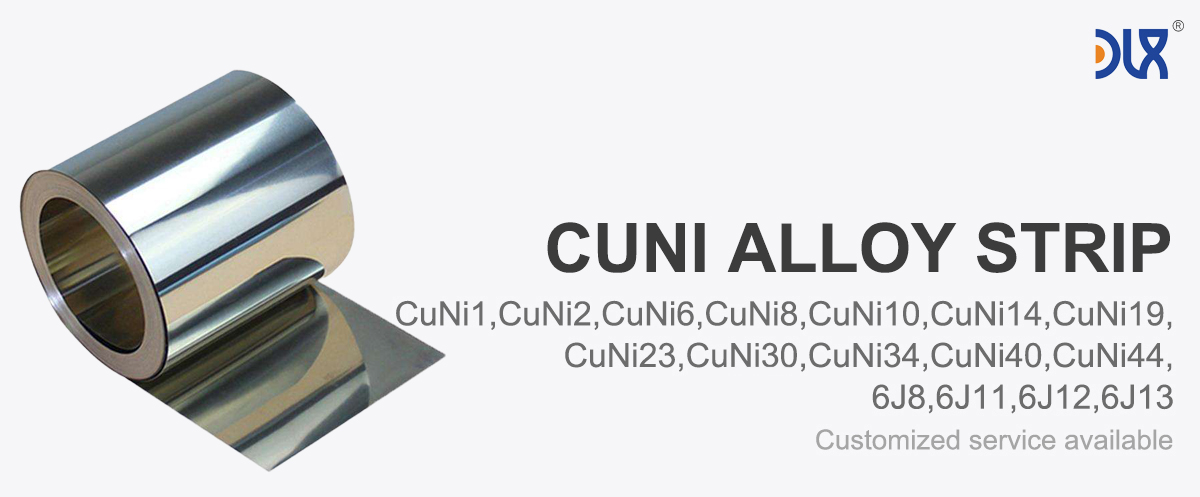

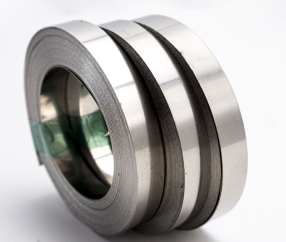

Cheap Price 8.9g/cm3 Hardness Range of 80-120HV With Low Resistivity CuNi Alloy Strip

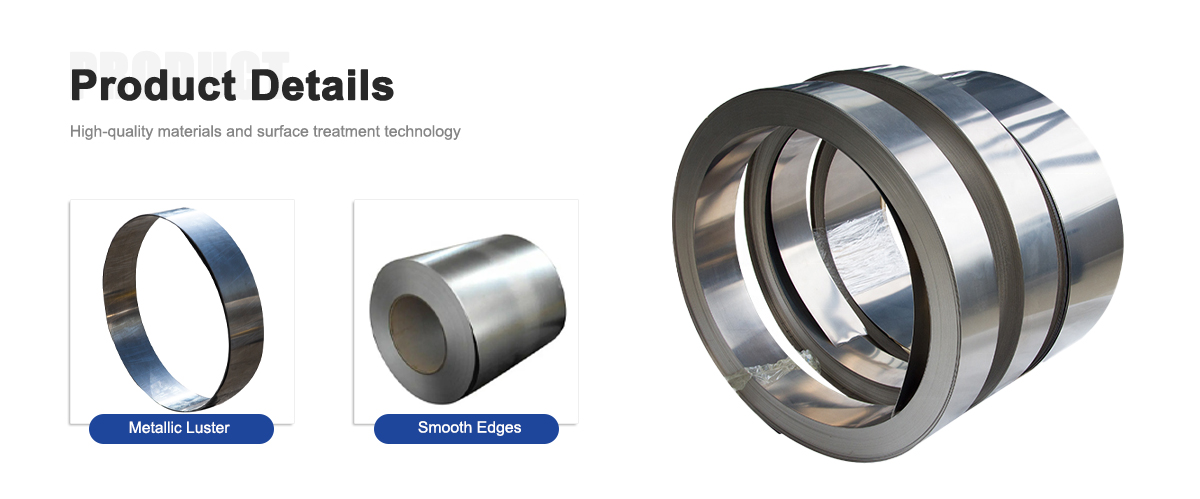

- Product Details

Our CuNi alloy strip, with a density of 8.9g/cm³ and a hardness range of 80-120HV, is a total game-changer for industries needing reliable, cost-effective materials. This copper-nickel alloy, typically packing 10-45% nickel, nails it with low electrical resistivity, awesome corrosion resistance, and just the right toughness to handle demanding jobs—all at a price that won’t break the bank.

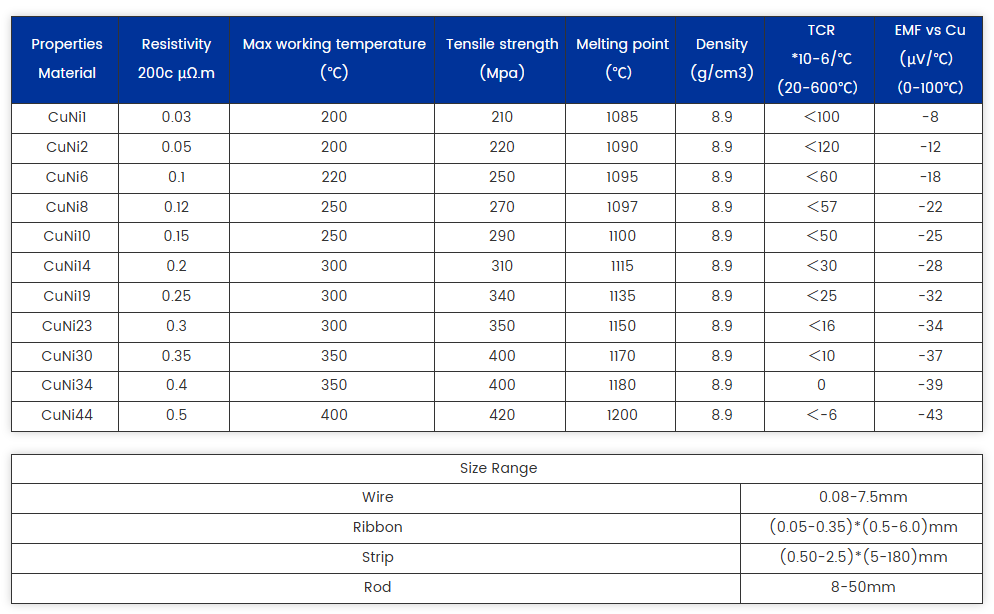

Let’s break it down. This strip is a superstar in harsh environments, especially where saltwater’s involved. Its corrosion resistance makes it a go-to for marine applications like seawater piping, desalination plants, and offshore oil rigs. We’ve seen it thrive in shipbuilding and even hydraulic systems, where it holds up without rusting or degrading. Plus, with a low resistivity of around 0.4-0.5 µΩ·m, it’s perfect for electrical components like resistors, heating cables, and circuit breakers, ensuring efficient current flow without overheating.

The hardness range of 80-120HV gives it just enough grit to resist wear and tear, making it ideal for automotive connectors, electronic switches, and battery components. It’s tough but still easy to work with—welding and forming this strip is a breeze, which saves time and money during manufacturing. Compared to pricier high-nickel alloys or specialty materials like Hastelloy, our CuNi strip delivers similar performance at a fraction of the cost, which is why it’s flying off our shelves.

The industry’s buzzing about copper-nickel alloys right now, and for good reason. Demand’s climbing—think a growth rate of about 5-6% annually—thanks to booming sectors like marine engineering, renewable energy, and electronics. With global pushes for desalination to tackle water shortages and more offshore wind farms popping up, this alloy’s corrosion resistance and durability are in high demand. Even in automotive, it’s sneaking into brake lines and cooling systems because it’s softer than steel but doesn’t rust.

We’re not just riding the trend—we’re pushing it forward. Our CuNi strip is produced with tight quality controls to hit that sweet spot of 8.9g/cm³ density and 80-120HV hardness, ensuring consistent performance. We’re also exploring greener production methods, like recycling nickel alloys, to keep costs low and sustainability high. Sure, raw material prices can fluctuate, but this alloy’s long lifespan and low maintenance make it a smart investment.

In short, our CuNi alloy strip is your ticket to high performance without the hefty price tag. Whether you’re building ships, wiring electronics, or designing energy systems, this strip’s got the strength, corrosion resistance, and versatility to get the job done. It’s no wonder it’s one of our best sellers—reliable, affordable, and ready to tackle your toughest projects.

Specification

For more details, pls directly contact us.

Product Description:

Our CuNi alloy has a hardness range of 80-120 HV, which means it is extremely resistant to wear and tear. The high hardness of this copper bronze alloy makes it ideal for use in applications where the material is subjected to high levels of stress or friction. Additionally, our CuNi alloy has a resistivity of 0.5, which makes it an excellent conductor of electricity. This property makes it perfect for use in electrical wiring and other applications where electrical conductivity is essential.

Our copper based alloys are also known for their high tensile strength. The tensile strength of our CuNi alloy ranges from 400-600 MPa, which means it can withstand a lot of force without breaking or bending. This property makes it ideal for use in applications where the material is subjected to heavy loads or stress.

In addition to its mechanical properties, our copper bronze alloy is also highly pure. We use only the highest quality copper and nickel to create our CuNi alloy, ensuring that it is free from impurities that can compromise its performance. Our high purity copper based alloys are perfect for use in applications where the material must be free from contamination, such as in the medical or food industries.

In summary, our CuNi alloy is a highly versatile and durable copper bronze alloy that is perfect for use in a variety of applications. With its excellent combination of hardness, resistivity, and tensile strength, our copper based alloys are ideal for use in applications where the material is subjected to high levels of stress or friction. Additionally, our high purity copper bronze alloy is perfect for use in applications where the material must be free from contamination.

Features:

Product Name: CuNi Alloy

Emf Vs Cu: -18 UV/C

Composition: Copper And Nickel

Corrosion Resistance: Excellent

Hardness: 80-120 HV

Purity: High Purity

Our CuNi Alloy is a highly reliable and durable material that is composed of copper and nickel. With excellent corrosion resistance, it is an ideal choice for various applications. Its hardness ranges from 80-120 HV, making it an excellent choice for use in Copper Powder Metallurgy, Copper Bronze Alloy, and Copper Nickel Alloy products. Additionally, it boasts high purity, ensuring consistent quality and performance.

Applications:

The CuNi Alloy is commonly used in the production of copper alloy tubes, which are used in a variety of industries, including plumbing, HVAC, and automotive. The copper alloy tubes are strong, durable, and resistant to corrosion, making them ideal for use in harsh environments.

Another application for DLX's CuNi Alloy is in the manufacturing of heat exchangers. The alloy's high thermal conductivity makes it an excellent choice for heat transfer applications. The CuNi Alloy is also commonly used in the production of marine components, such as propellers and valves, due to its resistance to seawater corrosion.

In addition to its industrial applications, DLX's CuNi Alloy is also used in the production of jewelry. The alloy's unique properties make it an attractive choice for designers looking to create jewelry that is both durable and aesthetically pleasing.

The CuNi Alloy is produced in China and is composed of copper and nickel. The alloy has an EMF vs Cu of -18 UV/C, making it a reliable choice for a variety of applications. Whether you are producing copper alloy tubes, heat exchangers, marine components, or jewelry, DLX's CuNi Alloy is a versatile and reliable choice.

Support and Services:

Our CuNi alloy product comes with comprehensive technical support and services to ensure that our customers receive the best possible assistance and guidance. Our expert team is available to provide assistance with installation, maintenance, and troubleshooting, as well as to answer any questions related to the product's performance or technical specifications. We also offer training to help customers optimize the use of our CuNi alloy product, as well as custom engineering and design services to meet specific customer needs. Our commitment to quality means that we stand behind our products and offer reliable warranty and repair services.

Packing and Shipping:

Product Packaging:

The CuNi alloy product will be packed in high-quality, sturdy boxes to ensure safe transportation.

Each box will contain a specified quantity of the product, as per the customer's requirements.

The boxes will be labeled with the product name, code, and quantity to ensure easy identification.

Special packaging requirements can be accommodated upon request.

Shipping:

Our shipping department will arrange for the safe and timely delivery of the CuNi alloy product.

Shipping options include air, sea, and land transport, based on the customer's preference and urgency of delivery.

We work with reliable courier services to ensure that the product reaches the customer's location in good condition.

Customers can track their shipment through our online tracking system.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

What is the CuNi alloy strip with 8.9g/cm³ density?

It’s a copper-nickel alloy strip, typically with 10-45% nickel, known for low resistivity, corrosion resistance, and a hardness range of 80-120HV.

What applications suit this CuNi alloy strip?

It’s used in electrical components like resistors, heating cables, marine hardware, and seawater piping due to its low resistivity and corrosion resistance.

How does its corrosion resistance perform in marine settings?

It’s highly resistant to seawater corrosion, making it ideal for shipbuilding, desalination plants, and offshore oil platforms.

Is the strip easy to work with?

Yes, its excellent weldability and formability make it easy to shape and process for various manufacturing needs.

What’s the hardness range, and why does it matter?

The 80-120HV hardness ensures durability and resistance to wear, suitable for high-stress applications like connectors and terminals.

How does its resistivity compare to other alloys?

Its low resistivity (around 0.4-0.5 µΩ·m) makes it better for electrical applications than higher-resistivity alloys like nichrome.

What industries benefit most from this alloy?

Marine, electronics, automotive, and energy sectors use it for its cost-effectiveness and reliable performance in tough conditions.

Is this alloy cost-effective?

Absolutely, it offers a great balance of performance and price, especially compared to high-nickel or specialty alloys.

-

Low Resistivity With High Temperature Customized CuNi Alloy Strip For Sale

Enquire Now -

CuNi Alloy NC010(CuNi6)The Optimal Solution for High-Temperature and High-Pressure Applications

Enquire Now -

8.94 G/cm3 CuNi Alloy NC005(CuNi2) with High Tensile Strength and Hardness

Enquire Now -

Upgrade Your Manufacturing Process with CuNi Alloy NC003(CuNi1)

Enquire Now