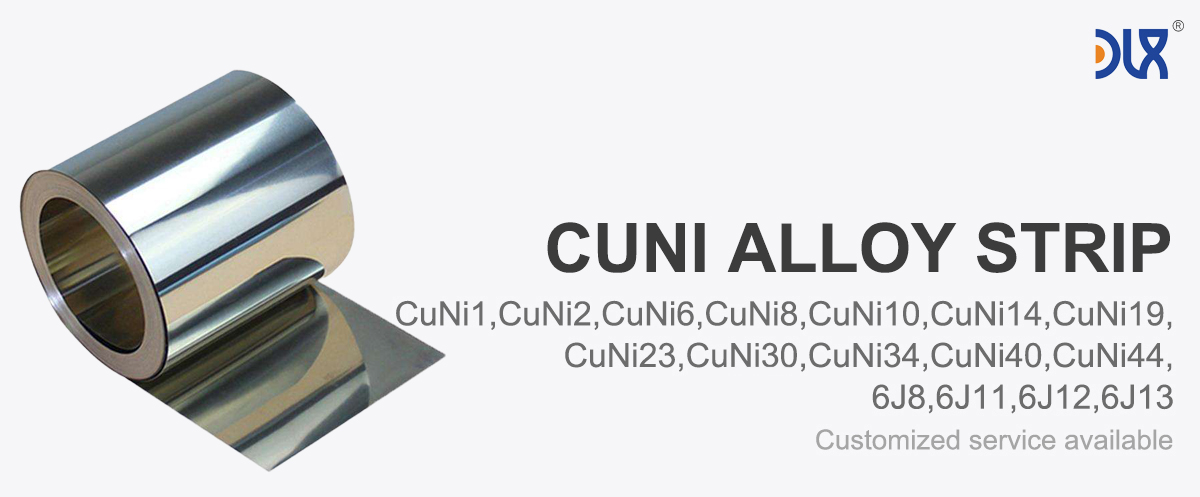

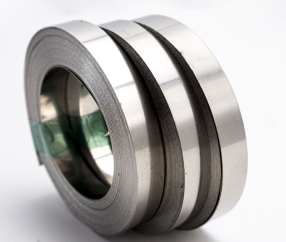

CuNi Alloy NC010(CuNi6)The Optimal Solution for High-Temperature and High-Pressure Applications

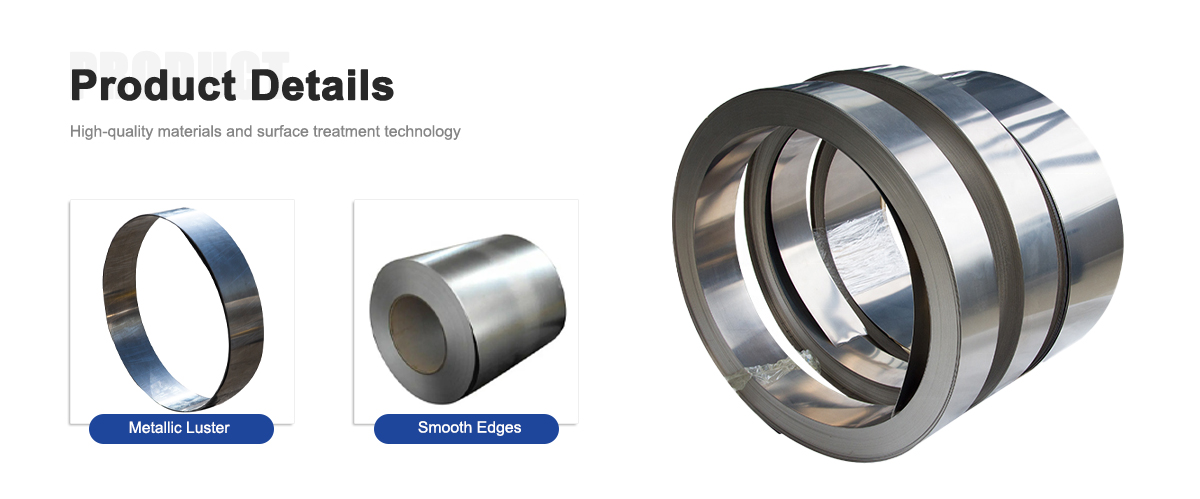

- Product Details

Our CuNi Alloy NC010, better known as CuNi6, is a standout choice for tackling high-temperature and high-pressure applications without breaking the bank. With just 6% nickel and a copper-heavy makeup, this alloy delivers low electrical resistivity, solid corrosion resistance, and the toughness to handle demanding environments—making it a favorite across industries.

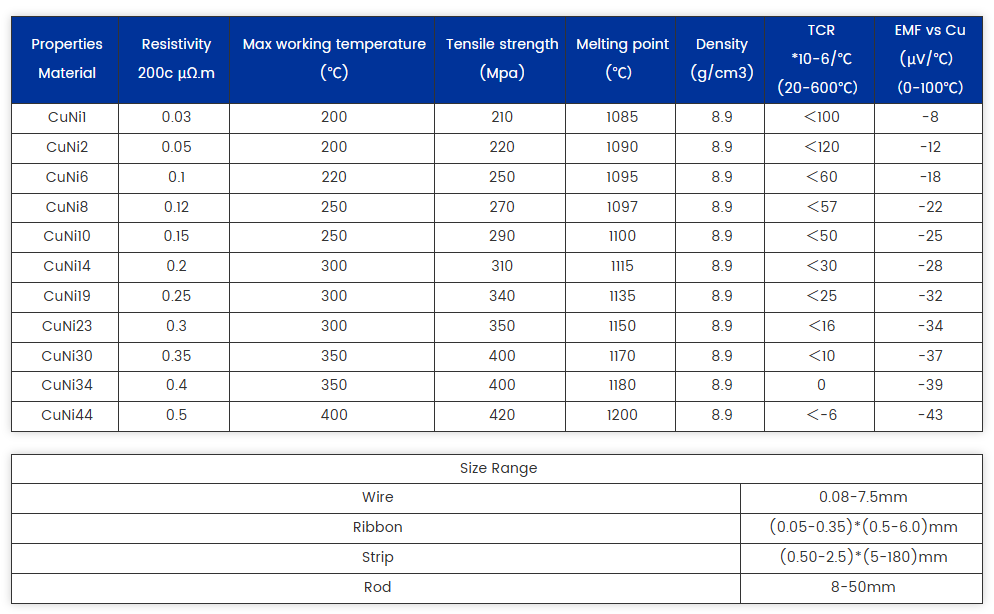

Let’s talk performance. CuNi6’s low resistivity, around 0.1-0.2 µΩ·m, makes it a champ for electrical applications like heating cables, resistors, and thermal overload relays. It’s perfect for systems where efficient current flow is key, without generating excessive heat. Plus, it holds its own up to 300°C, which is great for low to medium-temperature setups like heating cords or electrical fittings. When it comes to high-pressure environments, CuNi6’s strength and ductility shine, especially in marine systems like seawater piping or heat exchangers, where it stands up to both pressure and corrosion.

Speaking of corrosion, this alloy is a beast in harsh settings. Its ability to form a protective oxide layer makes it a top pick for marine applications—think shipbuilding, desalination plants, or offshore oil rigs. It laughs off seawater corrosion, which is why it’s so popular for piping and fittings in salty environments. And because it’s highly ductile and weldable, we can shape it into whatever you need, from intricate resistor components to robust marine hardware, without losing its integrity.

The market for copper-nickel alloys like CuNi6 is heating up, with demand growing at about 5-6% a year. Industries like marine engineering, renewable energy, and electronics are driving this, especially with the rise of desalination projects and offshore wind farms. CuNi6 fits right in, offering a cost-effective alternative to higher-nickel alloys like CuNi44 while still delivering reliable performance. Its lower nickel content keeps costs down, but you’re not sacrificing quality—especially for applications that don’t need extreme temperature resistance.

We’re all about quality and sustainability here. Our CuNi6 is produced with strict controls to ensure consistent resistivity and mechanical properties. We’re also exploring greener production methods, like recycling nickel alloys, to keep our footprint light. While raw material prices can fluctuate, CuNi6’s long lifespan and minimal maintenance make it a smart investment for projects needing durability on a budget.

In short, our CuNi Alloy NC010 (CuNi6) is your go-to for high-temperature and high-pressure challenges. It’s reliable, versatile, and easy to work with, whether you’re wiring up electrical systems, building marine equipment, or designing energy-efficient components. This alloy’s got the performance and price point to make your next project a success.

Specification

For more details, pls directly contact us.

Product Description:

This particular CuNi Alloy is available in both hard and soft conditions, which makes it a versatile material for use in a variety of applications. The hard condition is ideal for applications that require high strength and durability, while the soft condition is ideal for applications that require good formability and flexibility.

The surface of this CuNi Alloy is bright, which gives it an attractive appearance and makes it ideal for use in decorative applications. The bright surface also helps to enhance the corrosion resistance of the material, making it more durable and long-lasting.

This CuNi Alloy has a resistivity of 0.5, which makes it an excellent choice for use in electrical applications. Its high electrical conductivity ensures that it can carry current efficiently, while its low resistivity minimizes energy loss and helps to maintain the overall efficiency of the system.

Overall, the CuNi Alloy is a versatile and reliable material that is widely used in various industrial applications. Its high resistance to corrosion and oxidation, excellent thermal and electrical conductivity, and bright surface make it an ideal choice for a range of different applications. Whether you need a hard or soft material, this copper bronze alloy is sure to meet your needs and exceed your expectations.

Features:

Product Name: CuNi Alloy

Surface: Bright

Sureface: Bright

Condition: Hard / Soft

Composition: Copper And Nickel

Application: Industry

Alloy Steel Material

Copper Powder Metallurgy

Copper Powder Metallurgy

Applications:

Copper metal products are widely used in the manufacturing industry, especially in the production of electronic components, such as connectors and switches. Victory's CuNi Alloy can be used in copper powder metallurgy and as a substitute for copper in electronic components. Its high thermal expansion coefficient of 16.5 X 10^-6/K makes it ideal for use in applications where dimensional stability is important, such as in electrical contacts.

Due to its excellent corrosion resistance, CuNi Alloy can also be used in marine applications, such as in the construction of boats and ships. Its bright surface adds an aesthetic appeal to the finished product.

Victory's CuNi Alloy has a maximum temperature of 200℃, making it suitable for use in high temperature applications. It can be used in the automotive industry, specifically in the production of engine parts, where high temperatures are common.

In addition to the above-mentioned applications, CuNi Alloy can also be used in the chemical industry, where it can withstand harsh chemical environments. It can be used in the production of chemical processing equipment, heat exchangers, and storage tanks.

In conclusion, Victory's CuNi Alloy is a highly versatile and reliable copper based alloy product that can be used in a wide range of industries. Its high purity, excellent corrosion resistance, and thermal expansion coefficient make it an ideal choice for many applications, such as in copper powder metallurgy and the manufacturing of electronic components, boats and ships, engine parts, and chemical processing equipment.

Customization:

Our custom product customization services for Victory CuNi Alloy, a copper based alloy steel material, from China, is perfect for industries that require high EMF vs Cu (-18 UV/C) and maximum temperature resistance of up to 200℃. Our CuNi Alloy has a composition of copper and nickel, with a tensile strength of 400-600 MPa. We specialize in copper metal products and can provide customized solutions to meet your specific requirements.

Support and Services:

Our CuNi alloy product is supported by a team of technical experts who can provide assistance with product selection, installation, and maintenance. We also offer a range of services including testing, analysis, and custom fabrication to meet specific customer requirements. Our team is committed to ensuring the highest level of product performance and customer satisfaction.

Packing and Shipping:

Product Packaging:

Each CuNi Alloy product will be packed in a sturdy cardboard box.

The box will be labeled with the product name, quantity, and batch number.

Inside the box, the product will be securely wrapped in bubble wrap or foam to prevent damage during shipping.

Shipping:

All orders will be shipped within 1-2 business days of receiving payment.

Shipping options include standard ground, 2-day, and overnight delivery.

Shipping costs will vary based on the weight and destination of the package.

Customers will receive a tracking number via email once the package has shipped.

International orders may be subject to additional customs fees and taxes.

About Us:

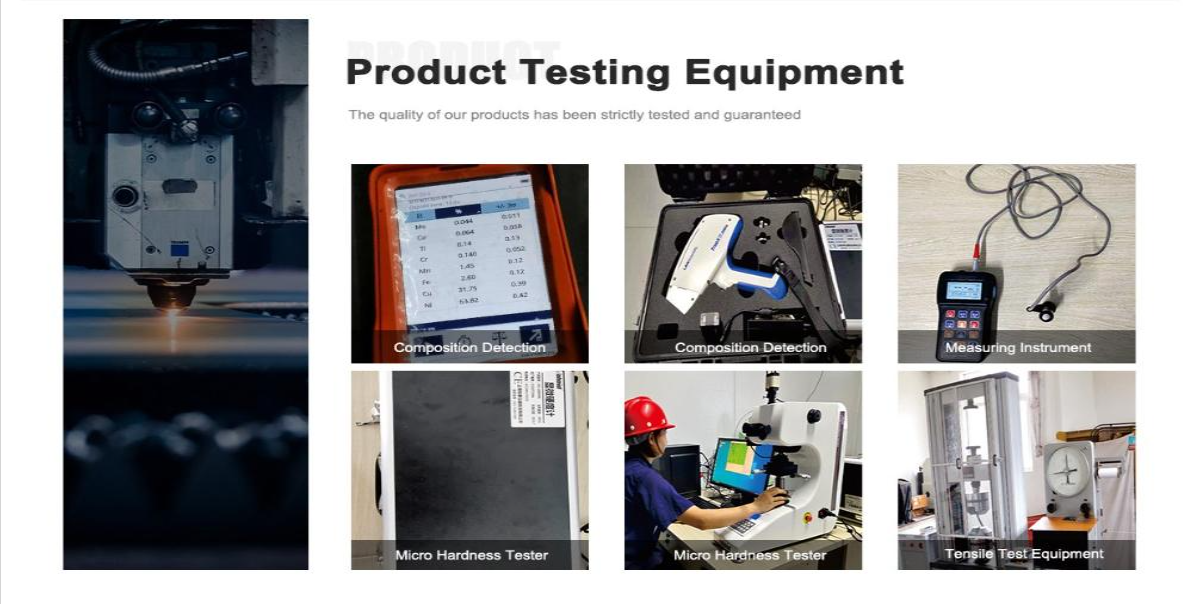

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

What is CuNi Alloy NC010 (CuNi6)?

It’s a copper-nickel alloy with approximately 6% nickel (Cu94Ni6), known for low resistivity and suitability for temperatures up to 300°C, ideal for heating and electrical applications.

What are its primary applications?

It’s used in heating cables, resistors, thermal overload relays, and marine components due to its low resistivity and corrosion resistance.

How does CuNi6 perform in high-temperature environments?

It remains stable up to 300°C, making it suitable for low to medium-temperature applications like heating cords and electrical fittings.

Is CuNi6 suitable for high-pressure applications?

Yes, its good strength and ductility make it reliable in high-pressure systems like marine piping and heat exchangers, especially when cold-worked.

How does its corrosion resistance hold up?

CuNi6 excels in marine and aqueous environments, forming a protective oxide layer that resists corrosion, ideal for seawater applications.

How does its resistivity compare to other alloys?

With a resistivity of around 0.1-0.2 µΩ·m, it’s lower than higher-nickel CuNi alloys (e.g., CuNi44 at 0.4-0.5 µΩ·m), making it better for low-resistance applications.

What industries use CuNi6 the most?

Electrical, marine, chemical processing, and renewable energy sectors rely on it for heating elements, seawater piping, and precision resistors.

Is CuNi6 easy to work with?

Absolutely, its high ductility and weldability make it easy to form and join, perfect for complex components in manufacturing.

-

Cheap Price 8.9g/cm3 Hardness Range of 80-120HV With Low Resistivity CuNi Alloy Strip

Enquire Now -

Low Resistivity With High Temperature Customized CuNi Alloy Strip For Sale

Enquire Now -

8.94 G/cm3 CuNi Alloy NC005(CuNi2) with High Tensile Strength and Hardness

Enquire Now -

Upgrade Your Manufacturing Process with CuNi Alloy NC003(CuNi1)

Enquire Now