CuNi Alloy Strip The Trusted Choice for High-Performance and Corrosion Resistance

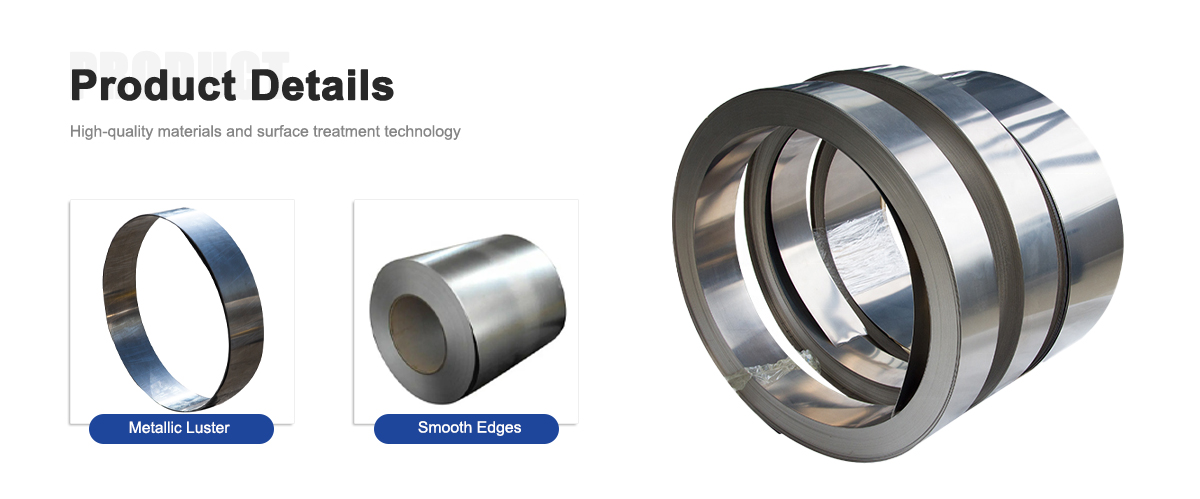

- Product Details

Our CuNi alloy strip is the trusted choice for manufacturers who need materials that deliver top-notch performance without failing in tough conditions. With nickel content ranging from 1-45%, this strip offers a killer combo of corrosion resistance, low electrical resistivity, and durability that makes it a staple in industries like marine, electrical, and renewable energy.

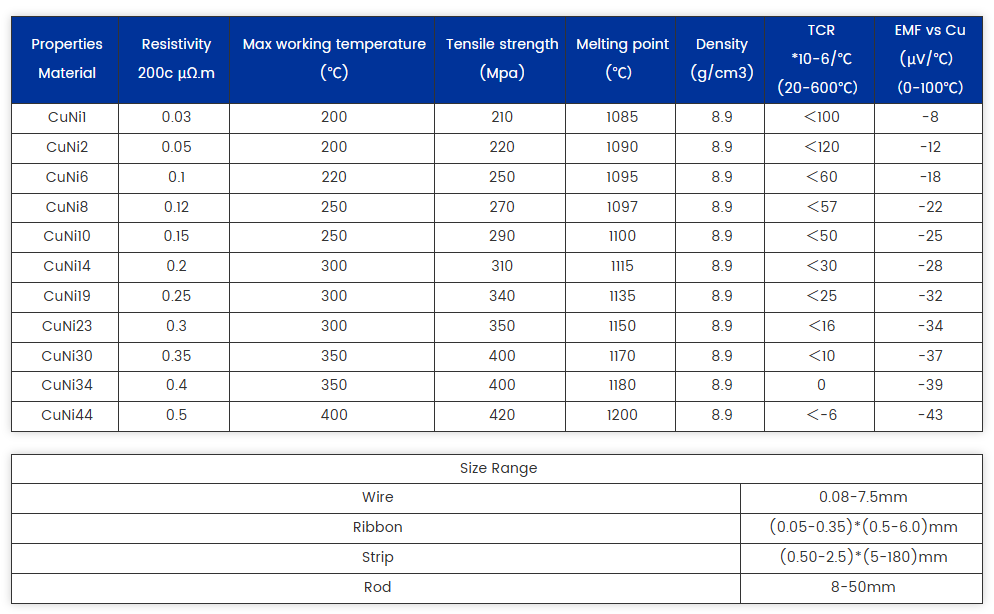

Let’s talk about what makes this strip so reliable. Its corrosion resistance is next-level, especially in seawater, where it forms a protective oxide layer that laughs off rust. That’s why it’s a favorite for marine applications like ship fittings, desalination piping, and offshore oil rig components. Its low resistivity—anywhere from 0.03-0.5 µΩ·m depending on the alloy—makes it a go-to for electrical components like resistors, heating cables, and connectors, ensuring efficient current flow without overheating.

This strip’s strength is another big win. With tensile strength ranging from 280-600 MPa and hardness from 70-150 HV, it’s tough enough for high-stress environments but still ductile and weldable for easy shaping. Whether you’re crafting intricate electrical parts or sturdy marine hardware, this alloy is a breeze to work with. It’s also stable across a wide temperature range, from 200°C for low-nickel versions like CuNi1 to 600°C for high-nickel ones like CuNi44, making it versatile for heating systems or high-temperature setups.

The copper-nickel alloy market is growing fast, with a CAGR of about 5-6%, fueled by demand in marine, electronics, and renewable energy. Desalination plants, offshore wind farms, and electric vehicle components are driving the need for materials like our CuNi strip that can handle harsh conditions while keeping costs low. Compared to pricier options like nichrome or high-nickel alloys, our strip delivers similar performance at a fraction of the cost, especially for applications that don’t need extreme heat resistance.

We produce this CuNi strip with strict quality controls to ensure consistent resistivity, strength, and corrosion resistance. We’re also pushing for sustainability, exploring recycling options to keep our process eco-friendly. While raw material prices can be a bit of a rollercoaster, the long lifespan and low maintenance of this alloy make it a smart investment for manufacturers.

In a nutshell, our CuNi alloy strip is the reliable, high-performance choice you need for projects that demand corrosion resistance and efficiency. From marine hardware to electrical systems, it’s built to perform, easy to work with, and budget-friendly. Ready to elevate your manufacturing? This strip’s got your back.

Specification

For more details, pls directly contact us.

Product Description:

The Copper Bronze Alloy consists of copper and nickel, with a small percentage of iron and manganese. This combination of metals results in a material that is highly resistant to corrosion, making it ideal for use in environments that are exposed to harsh conditions. It is also known for its high strength and durability, making it a popular choice for applications that require a material that can withstand wear and tear.

In addition to its excellent corrosion resistance and strength, the Inconel Nickel Alloy also has a bright surface finish, which makes it visually appealing. The alloy is available in a range of diameters, from 0.1mm to 10mm, making it suitable for use in a wide range of applications.

The Copper Powder Metallurgy is a cost-effective manufacturing process that is used to produce the CuNi Alloy. This process involves the use of copper and nickel powders, which are combined and pressed into the desired shape. The resulting material is then sintered at high temperatures, resulting in a dense and highly durable product.

Overall, the CuNi Alloy is a versatile and reliable material that is widely used in the industry for its excellent corrosion resistance, high strength, and durability. Its bright surface finish and availability in various diameters make it a practical choice for a range of applications.

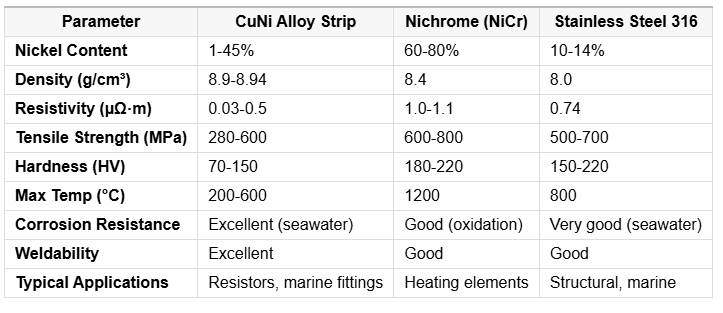

Comparison Table: CuNi Alloy Strip vs. Other Materials

Features:

Product Name: CuNi Alloy

Resistivity: 0.5

Hardness: 80-120 HV

Maximum Temperature: 200℃

Thermal Expansion Coefficient: 16.5 X 10^-6/K

Purity: High Purity

This Copper Bronze Alloy is a type of Alloy Steel Metal that is often used in manufacturing Copper Alloy Tubes.

Applications:

The CuNi alloy is commonly used in the manufacturing of copper metal products. This alloy is used extensively in the construction industry for applications such as electrical wiring, plumbing, and heating systems. It is also used in the production of coins, medals, and decorative items. The DLX CuNi Alloy is perfect for these applications due to its high purity and diameter range of 0.1~10mm.

The copper nickel alloy is also used in the production of copper powder metallurgy. This process is used to create complex shapes and parts that are difficult to manufacture using other methods. The DLX CuNi Alloy is an ideal choice for powder metallurgy due to its unique composition and high purity. This alloy is used in a wide range of industries, such as automotive, aerospace, and defense.

There are several occasions and scenarios where the DLX CuNi Alloy product can be used. For example, this alloy is ideal for use in the manufacturing of electrical components such as resistors and capacitors. It is also used in the production of heat exchangers and condensers. In the automotive industry, the CuNi alloy is used in the production of brake lines and fuel lines. It is also used in the construction of ship hulls and propellers.

In conclusion, the DLX CuNi Alloy is a versatile and unique product that has a wide range of applications in various industries. Its high purity, thermal expansion coefficient, and unique composition make it an ideal choice for use in copper metal products, copper nickel alloy, and copper powder metallurgy. This product is made in China and is available in a diameter range of 0.1~10mm. Its versatility makes it an excellent choice for use in a variety of applications.

Customization:

Looking for customized CuNi Alloy products? Look no further than DLX! Our CuNi Alloy products are made in China with a tensile strength of 400-600 MPa and a diameter range of 0.1~10mm. The composition of our CuNi Alloy products is a combination of copper and nickel, with an Emf Vs Cu of -18 UV/C and a hardness of 80-120 HV.

At DLX, we offer product customization services to meet your specific needs. Whether you're looking for copper metal products, copper bronze alloy, or copper powder metallurgy, we can create the perfect product for you. Contact us today to learn more!

Support and Services:

Our CuNi alloy products are designed to meet the highest technical standards for various industries. Our technical support team is available to assist you with any questions or concerns you may have about our products.

We offer a range of services to ensure that our CuNi alloy products meet your specific needs, including:

Custom alloy development

Product testing and analysis

Product selection guidance

Technical consultations

Training and education

Our team of experts has extensive knowledge and experience in the CuNi alloy industry, and we are committed to providing you with the highest level of support and service. Contact us today to learn more.

Packing and Shipping:

Product Name: CuNi Alloy

Quantity: 1kg

Dimensions: 20cm x 20cm x 10cm

Weight: 1.2kg

Shipping Method: Standard

Shipping Cost: $10

Estimated Delivery Time: 3-5 business days

About Us:

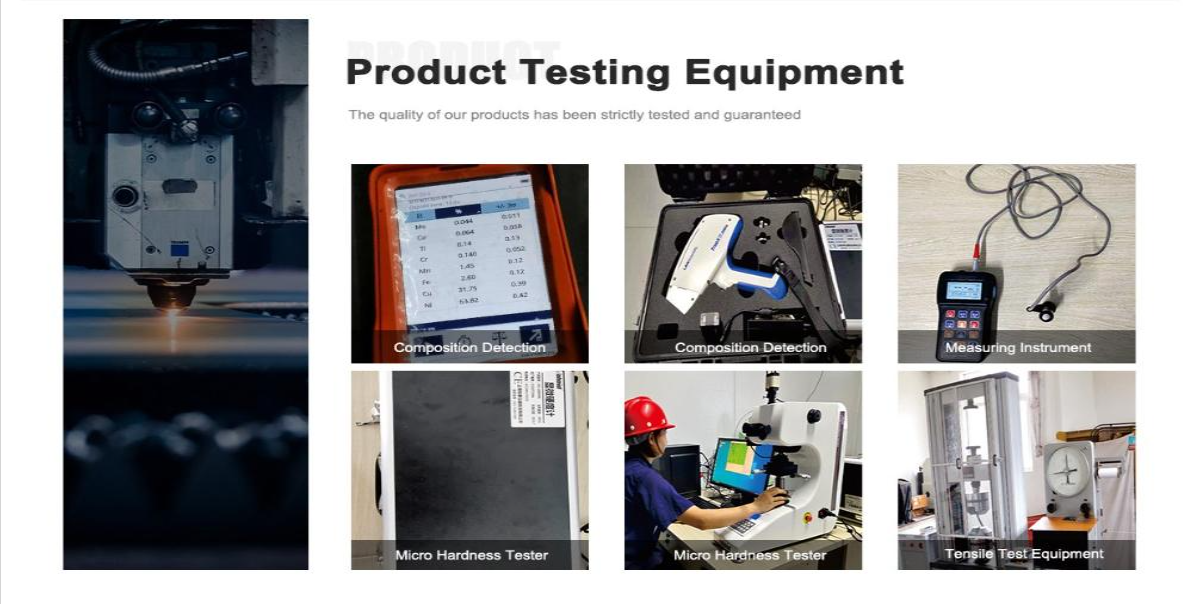

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

What is a CuNi alloy strip?

It’s a copper-nickel alloy strip, typically with 1-45% nickel, known for low resistivity, high corrosion resistance, and durability, used in electrical and marine applications.What are its main applications?

It’s used in resistors, heating cables, electrical connectors, marine fittings, and piping for desalination or offshore systems due to its conductivity and corrosion resistance.How does it perform in corrosive environments?

It excels in harsh settings like seawater, forming a protective oxide layer, making it ideal for marine hardware, valves, and piping.What’s its electrical resistivity like?

Depending on nickel content, resistivity ranges from 0.03-0.5 µΩ·m, offering high conductivity for electrical components like resistors and connectors.Is it suitable for high-temperature applications?

Yes, it’s stable from 200-600°C (depending on the alloy, e.g., CuNi1 vs. CuNi44), suitable for heating elements and high-temperature systems.Which industries rely on CuNi alloy strips?

Marine, electrical, automotive, renewable energy, and telecommunications sectors use it for its performance and cost-effectiveness.How does it compare to other alloys?

Compared to nichrome or stainless steel, CuNi strips offer better seawater corrosion resistance and lower resistivity, though with lower maximum temperature tolerance.Is it easy to process?

Absolutely, its high ductility and weldability make it easy to form and join, streamlining production for complex parts.

-

Cheap Price 8.9g/cm3 Hardness Range of 80-120HV With Low Resistivity CuNi Alloy Strip

Enquire Now -

Low Resistivity With High Temperature Customized CuNi Alloy Strip For Sale

Enquire Now -

CuNi Alloy NC010(CuNi6)The Optimal Solution for High-Temperature and High-Pressure Applications

Enquire Now -

8.94 G/cm3 CuNi Alloy NC005(CuNi2) with High Tensile Strength and Hardness

Enquire Now