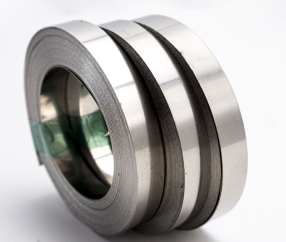

CuNi Alloy Strip with 16.5 x 10^-6/K Thermal Expansion Coefficient

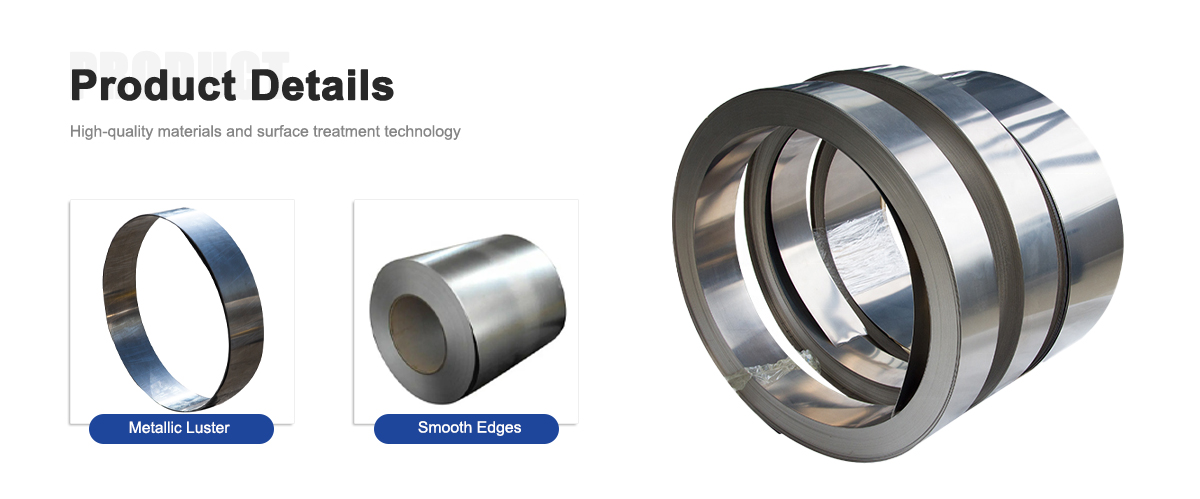

- Product Details

Our CuNi alloy strip, with a thermal expansion coefficient of 16.5 x 10^-6/K, is a powerhouse for manufacturers looking to balance performance, stability, and cost. Likely a low-nickel alloy like CuNi1 or CuNi2, this strip brings ultra-low electrical resistivity, top-tier corrosion resistance, and just the right thermal stability to keep your projects running smoothly.

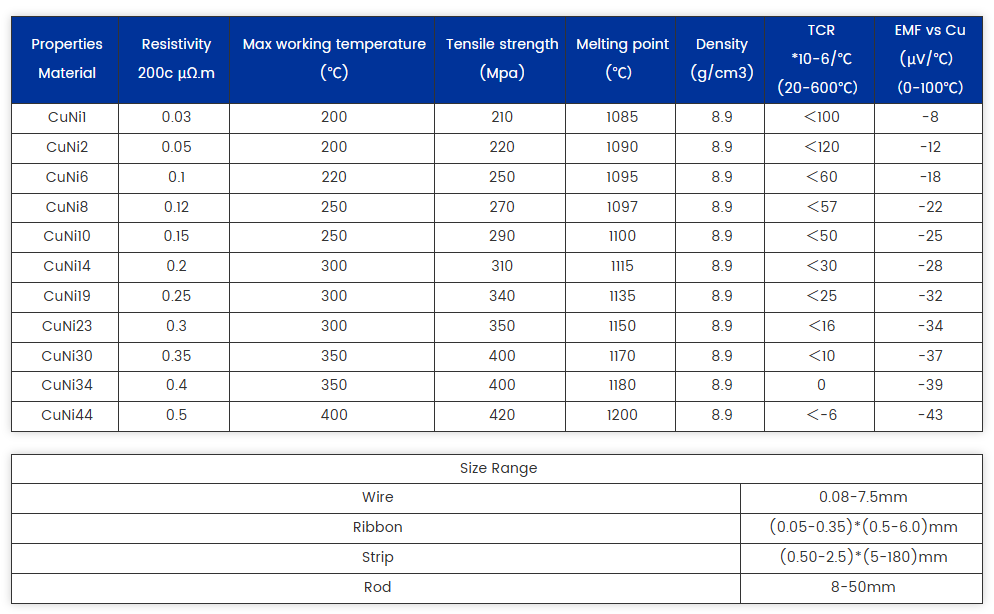

The 16.5 x 10^-6/K thermal expansion coefficient is a big deal—it means this strip stays dimensionally stable under temperature changes, making it perfect for precision components like electrical connectors, sensors, and resistors that face thermal cycling. Its low resistivity, around 0.03-0.1 µΩ·m, ensures efficient current flow, which is why it’s a favorite for heating wires, low-resistance resistors, and electrical fittings. And when it comes to tough environments, this alloy’s corrosion resistance is a game-changer, forming a protective oxide layer that thrives in seawater—ideal for marine fittings, valves, and piping in desalination plants or shipbuilding.

Manufacturers love how easy this strip is to work with. Its high ductility and weldability mean we can shape it into whatever you need, from intricate electrical parts to robust marine components, without a hitch. With a tensile strength of 280-450 MPa and hardness of 70-130 HV, it’s tough enough for demanding applications but still flexible for precision work. It’s stable up to 200-300°C, making it great for low to medium-temperature setups like automotive electrical systems or heating cables.

The copper-nickel alloy market is booming, with a growth rate of about 5-6% a year, driven by demand in marine, electrical, and renewable energy sectors. As desalination projects and offshore wind farms ramp up, this alloy’s corrosion resistance and affordability make it a top pick. Its lower nickel content compared to alloys like CuNi10 keeps costs down while delivering excellent conductivity, perfect for budget-conscious projects that still need high performance.

We produce this CuNi strip with strict quality controls to ensure consistent resistivity, strength, and thermal properties. We’re also committed to sustainability, exploring nickel alloy recycling to keep our process eco-friendly. While raw material prices can be a bit unpredictable, this strip’s long lifespan and low maintenance costs make it a smart investment for manufacturers.

In short, our CuNi alloy strip with a 16.5 x 10^-6/K thermal expansion coefficient is your ticket to upgrading your manufacturing game. Its conductivity, corrosion resistance, and thermal stability make it a versatile choice for electrical, marine, and automotive applications. Ready to take your production to the next level? This strip delivers the performance and value you need to get the job done.

Specification

For more details, pls directly contact us.

Product Description:

Our CuNi alloy has a hardness range of 80-120 HV, which means it is extremely resistant to wear and tear. The high hardness of this copper bronze alloy makes it ideal for use in applications where the material is subjected to high levels of stress or friction. Additionally, our CuNi alloy has a resistivity of 0.5, which makes it an excellent conductor of electricity. This property makes it perfect for use in electrical wiring and other applications where electrical conductivity is essential.

Our copper based alloys are also known for their high tensile strength. The tensile strength of our CuNi alloy ranges from 400-600 MPa, which means it can withstand a lot of force without breaking or bending. This property makes it ideal for use in applications where the material is subjected to heavy loads or stress.

In addition to its mechanical properties, our copper bronze alloy is also highly pure. We use only the highest quality copper and nickel to create our CuNi alloy, ensuring that it is free from impurities that can compromise its performance. Our high purity copper based alloys are perfect for use in applications where the material must be free from contamination, such as in the medical or food industries.

In summary, our CuNi alloy is a highly versatile and durable copper bronze alloy that is perfect for use in a variety of applications. With its excellent combination of hardness, resistivity, and tensile strength, our copper based alloys are ideal for use in applications where the material is subjected to high levels of stress or friction. Additionally, our high purity copper bronze alloy is perfect for use in applications where the material must be free from contamination.

Features:

Product Name: CuNi Alloy

Emf Vs Cu: -18 UV/C

Composition: Copper And Nickel

Corrosion Resistance: Excellent

Hardness: 80-120 HV

Purity: High Purity

Our CuNi Alloy is a highly reliable and durable material that is composed of copper and nickel. With excellent corrosion resistance, it is an ideal choice for various applications. Its hardness ranges from 80-120 HV, making it an excellent choice for use in Copper Powder Metallurgy, Copper Bronze Alloy, and Copper Nickel Alloy products. Additionally, it boasts high purity, ensuring consistent quality and performance.

Applications:

The CuNi Alloy is commonly used in the production of copper alloy tubes, which are used in a variety of industries, including plumbing, HVAC, and automotive. The copper alloy tubes are strong, durable, and resistant to corrosion, making them ideal for use in harsh environments.

Another application for DLX's CuNi Alloy is in the manufacturing of heat exchangers. The alloy's high thermal conductivity makes it an excellent choice for heat transfer applications. The CuNi Alloy is also commonly used in the production of marine components, such as propellers and valves, due to its resistance to seawater corrosion.

In addition to its industrial applications, DLX's CuNi Alloy is also used in the production of jewelry. The alloy's unique properties make it an attractive choice for designers looking to create jewelry that is both durable and aesthetically pleasing.

The CuNi Alloy is produced in China and is composed of copper and nickel. The alloy has an EMF vs Cu of -18 UV/C, making it a reliable choice for a variety of applications. Whether you are producing copper alloy tubes, heat exchangers, marine components, or jewelry, DLX's CuNi Alloy is a versatile and reliable choice.

Support and Services:

Our CuNi alloy product comes with comprehensive technical support and services to ensure that our customers receive the best possible assistance and guidance. Our expert team is available to provide assistance with installation, maintenance, and troubleshooting, as well as to answer any questions related to the product's performance or technical specifications. We also offer training to help customers optimize the use of our CuNi alloy product, as well as custom engineering and design services to meet specific customer needs. Our commitment to quality means that we stand behind our products and offer reliable warranty and repair services.

Packing and Shipping:

Product Packaging:

The CuNi alloy product will be packed in high-quality, sturdy boxes to ensure safe transportation.

Each box will contain a specified quantity of the product, as per the customer's requirements.

The boxes will be labeled with the product name, code, and quantity to ensure easy identification.

Special packaging requirements can be accommodated upon request.

Shipping:

Our shipping department will arrange for the safe and timely delivery of the CuNi alloy product.

Shipping options include air, sea, and land transport, based on the customer's preference and urgency of delivery.

We work with reliable courier services to ensure that the product reaches the customer's location in good condition.

Customers can track their shipment through our online tracking system.

About Us:

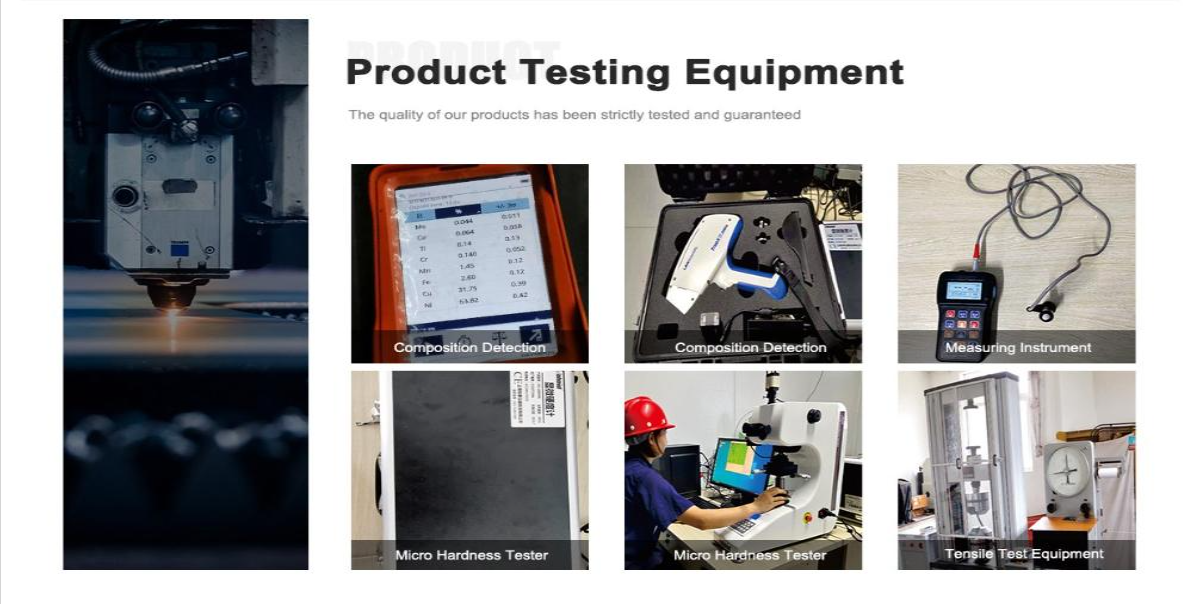

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

What is the CuNi alloy strip with a 16.5 x 10^-6/K thermal expansion coefficient?

It’s a copper-nickel alloy strip, likely with low nickel content (e.g., CuNi1 or CuNi2), offering a thermal expansion coefficient of 16.5 x 10^-6/K, ideal for applications needing dimensional stability.

What does the thermal expansion coefficient mean for this alloy?

The 16.5 x 10^-6/K coefficient means it expands moderately with temperature changes, ensuring stability in applications like connectors and sensors exposed to thermal cycling.

What are the main applications for this strip?

It’s used in electrical connectors, resistors, heating wires, and marine components due to its conductivity, corrosion resistance, and thermal stability.

How does it perform in corrosive environments?

It’s highly corrosion-resistant, especially in seawater, forming a protective oxide layer, making it ideal for marine fittings and piping.

How does its resistivity compare to other materials?

With a resistivity of around 0.03-0.1 µΩ·m (for low-nickel CuNi alloys), it’s highly conductive, outperforming higher-nickel alloys for low-resistance applications.

Is it suitable for high-temperature applications?

It’s stable up to 200-300°C, suitable for low to medium-temperature applications like heating cables and electrical components.

Which industries benefit most from this alloy?

Electrical, marine, telecommunications, and automotive sectors use it for its conductivity, corrosion resistance, and thermal stability.

Is this strip easy to manufacture with?

Yes, its high ductility and weldability make it easy to form and join, simplifying production of complex parts like connectors or marine hardware.

-

Cheap Price 8.9g/cm3 Hardness Range of 80-120HV With Low Resistivity CuNi Alloy Strip

Enquire Now -

Low Resistivity With High Temperature Customized CuNi Alloy Strip For Sale

Enquire Now -

CuNi Alloy NC010(CuNi6)The Optimal Solution for High-Temperature and High-Pressure Applications

Enquire Now -

8.94 G/cm3 CuNi Alloy NC005(CuNi2) with High Tensile Strength and Hardness

Enquire Now