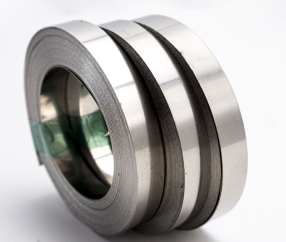

CuNi44 420 MPA Bright 2.5mmx180mm Resistance Strip CuNi Alloy OEM

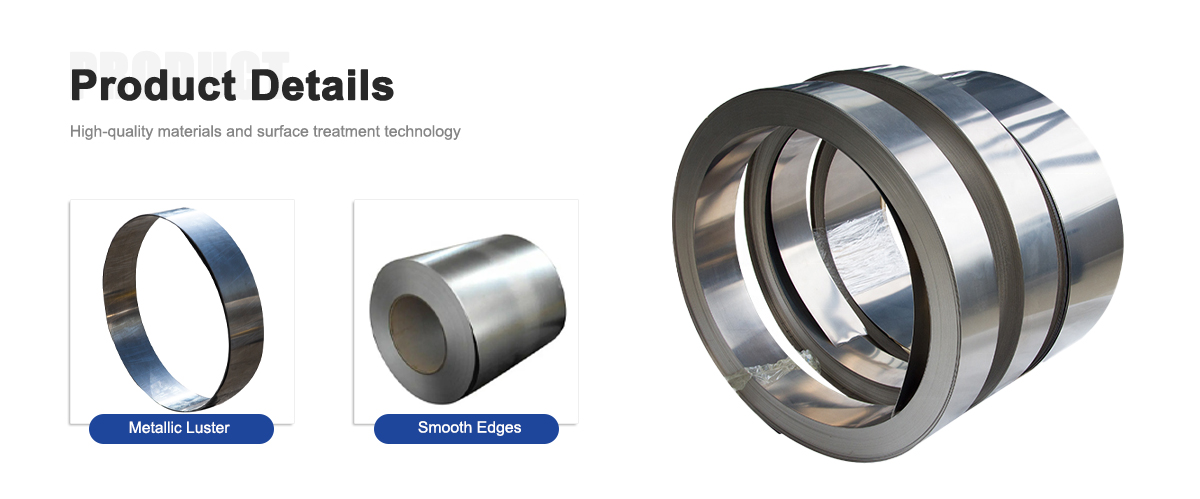

- Product Details

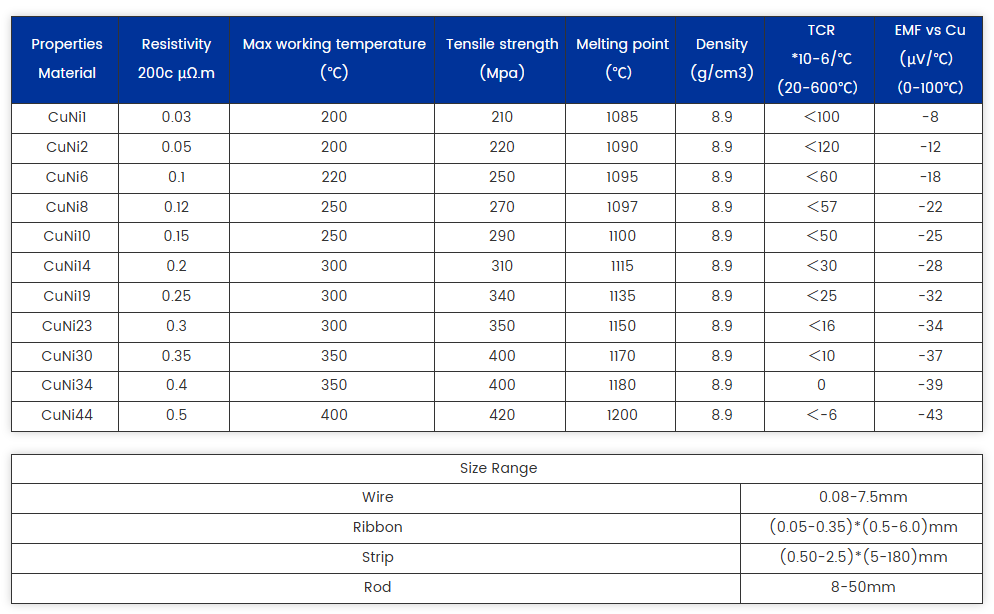

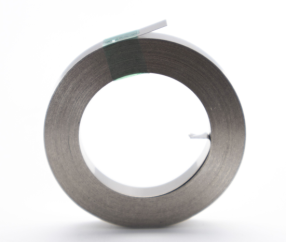

Our CuNi 44 resistance strip, with a 420 MPa tensile strength and bright 2.5mmx180mm finish, is a top-tier choice for OEMs looking for reliability and precision. Known as Constantan, this copper-nickel alloy (44% nickel, 56% copper) brings high electrical resistivity, stellar corrosion resistance, and a low temperature coefficient of resistance (TCR) that makes it a go-to for high-performance applications.

This strip’s resistivity of about 0.49 µΩ·m is perfect for precision resistors, potentiometers, and industrial rheostats, delivering stable performance even under temperature swings. Its low TCR ensures minimal resistance changes, which is why it’s a favorite for wire-wound resistors and thermocouple applications (like Type J and T thermocouples). Plus, it can handle temperatures up to 400-600°C, making it ideal for heating cables, mats, and electric motor starter resistances.

Corrosion resistance is where CuNi44 really flexes its muscles. It thrives in harsh environments like seawater, forming a protective oxide layer that makes it a staple for marine applications—think ship fittings or desalination plant components. Its bright finish not only looks sharp but also enhances its durability in corrosive settings. With a tensile strength of 420 MPa and hardness of 100-150 HV, this strip is tough enough for demanding mechanical applications while staying ductile and weldable for easy OEM customization.

The copper-nickel alloy market is buzzing, growing at about 5-6% annually, driven by demand in electrical, marine, and instrumentation sectors. With the rise of renewable energy and desalination projects, CuNi44’s corrosion resistance and stability are in high demand. Compared to nichrome, it offers better seawater corrosion resistance and lower resistivity, making it a cost-effective choice for precision applications that don’t need extreme heat tolerance.

We produce this 2.5mmx180mm CuNi44 strip with strict quality controls to ensure consistent resistivity, strength, and surface finish. Its bright surface is ready for immediate use in OEM processes, and we’re equipped to tailor it to your exact specs. We’re also pushing for sustainability, exploring recycling options to keep our process eco-friendly. While raw material costs can fluctuate, CuNi44’s long lifespan and low maintenance make it a smart investment for OEMs.

In short, our CuNi44 420 MPa bright 2.5mmx180mm resistance strip is a versatile, high-performance solution for your manufacturing needs. Whether you’re building precision resistors, thermocouples, or marine components, this alloy delivers the reliability, corrosion resistance, and ease of processing you need to get the job done right.

CuNi44, also known as Constantan, is a copper-nickel alloy with approximately 44% nickel content. The alloy you mentioned, "CuNi44 420 MPA Bright 2.5mmx180mm Resistance Strip," appears to be a specific form used for its resistance properties. Here are some detailed characteristics and applications of this alloy:

For more details, pls directly contact us.

Properties:

High Electrical Resistivity: CuNi44 has a high electrical resistivity, making it ideal for use in precision resistors and other electrical applications.

Low Temperature Coefficient of Resistance (TCR): This property ensures that the resistance remains stable over a wide range of temperatures.

Good Corrosion Resistance: The alloy exhibits excellent resistance to corrosion, particularly in neutral and mildly aggressive environments.

Mechanical Strength: With a tensile strength of 420 MPa, this alloy strip offers good mechanical properties.

Bright Finish: The bright finish indicates a polished surface, which might be important for certain aesthetic or functional requirements.

Uses:

Precision Resistors: CuNi44 is commonly used in the manufacture of precision resistors due to its stable resistance over a range of temperatures.

Heating Elements: It can be used in heating elements where stable resistance is crucial.

Thermocouples: CuNi44 is often used in thermocouple extension and compensating cables.

Electrical Resistance Wires: Due to its high resistivity, it is used in electrical resistance wires for various applications.

Strain Gauges: The alloy is used in strain gauges because of its consistent resistance characteristics under mechanical strain.

Specific Form - "2.5mmx180mm Resistance Strip":

Dimensions: The strip measures 2.5mm in thickness and 180mm in length.

Application: Such strips are typically used in applications where precise and stable electrical resistance is required. This could include custom resistor manufacturing, specific industrial applications, or experimental setups where exact dimensions and resistance values are crucial.

Overall, CuNi44 is valued for its stable electrical properties and resistance to environmental factors, making it a reliable material for precision electrical components.

About Us:

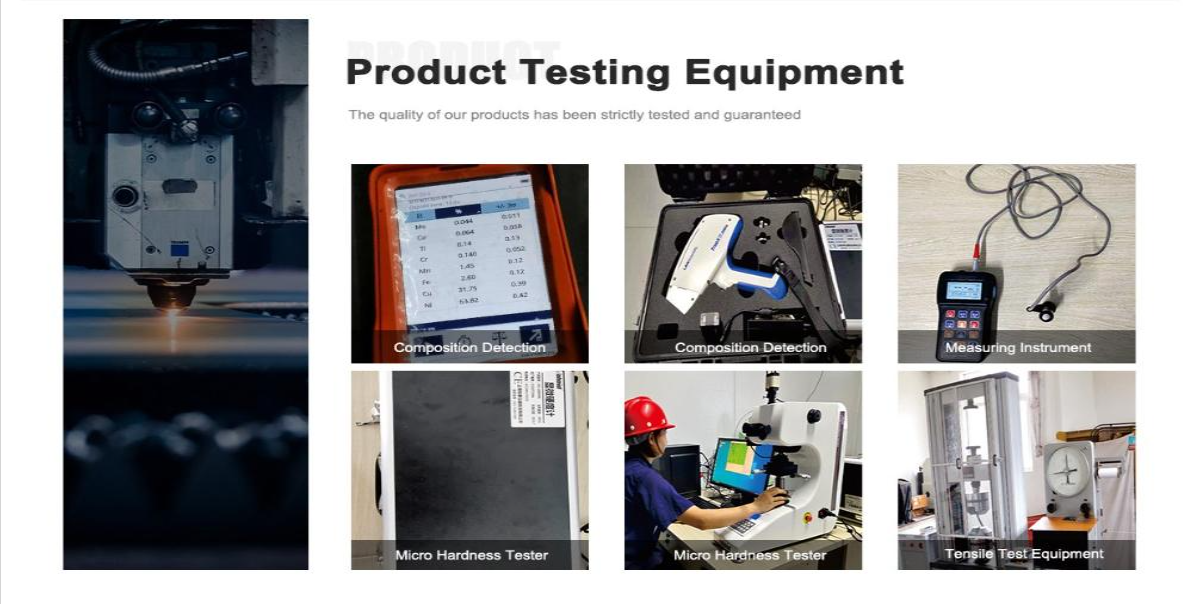

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

What is CuNi44 resistance strip?

CuNi44, also known as Constantan, is a copper-nickel alloy (44% nickel, 56% copper) with high electrical resistivity (~0.49 µΩ·m) and low TCR, ideal for precision resistors and thermocouples.

What applications is this strip used for?

It’s used in precision resistors, potentiometers, industrial rheostats, electric motor starter resistances, and thermocouples (Type J and T) due to its stable resistivity and corrosion resistance.

How does its corrosion resistance perform?

CuNi44 offers excellent corrosion resistance, particularly in seawater and atmospheric conditions, making it suitable for marine and industrial applications.

What does the 420 MPa strength indicate?

The 420 MPa tensile strength indicates good mechanical durability, suitable for components under moderate stress, like resistors and heating elements.

How does its resistivity compare to other alloys?

Its resistivity (~0.49 µΩ·m) is higher than CuNi1 (~0.03-0.08 µΩ·m) but lower than nichrome (~1.0-1.1 µΩ·m), making it ideal for precision applications.

Can it handle high temperatures?

Yes, it’s stable up to 400-600°C, depending on the application, making it suitable for heating cables and thermocouples.

Is it easy to process for OEM applications?

Its high ductility and weldability make it easy to form and customize into specific sizes like 2.5mmx180mm for OEM manufacturing.

Which industries use this CuNi44 strip?

Electrical, marine, automotive, and instrumentation industries rely on it for resistors, heating elements, and thermocouple components.

-

Cheap Price 8.9g/cm3 Hardness Range of 80-120HV With Low Resistivity CuNi Alloy Strip

Enquire Now -

Low Resistivity With High Temperature Customized CuNi Alloy Strip For Sale

Enquire Now -

CuNi Alloy NC010(CuNi6)The Optimal Solution for High-Temperature and High-Pressure Applications

Enquire Now -

8.94 G/cm3 CuNi Alloy NC005(CuNi2) with High Tensile Strength and Hardness

Enquire Now