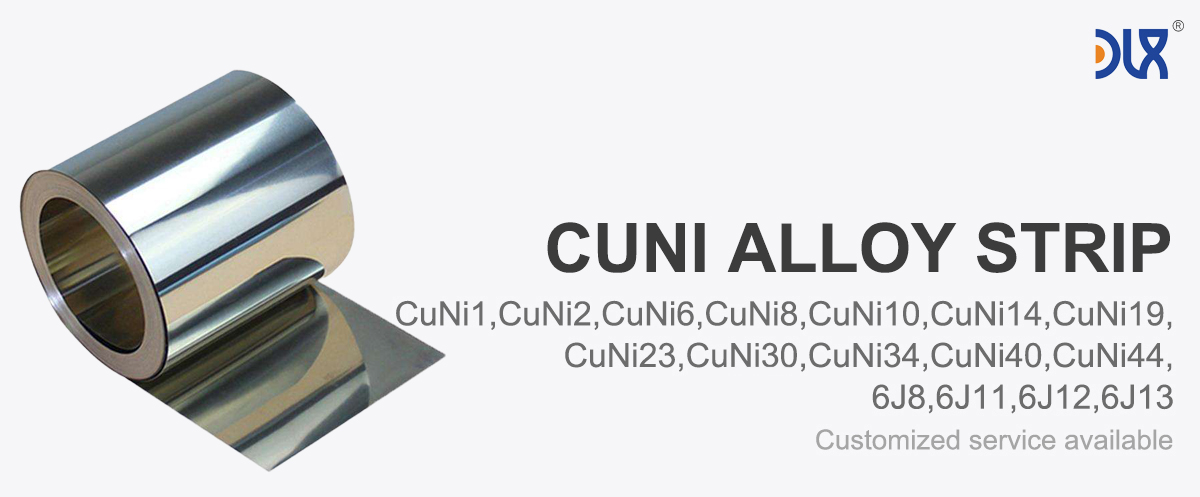

Best Selling Nickel Copper Alloy 400 0.5mmx180mm Soft MPA CuNi34

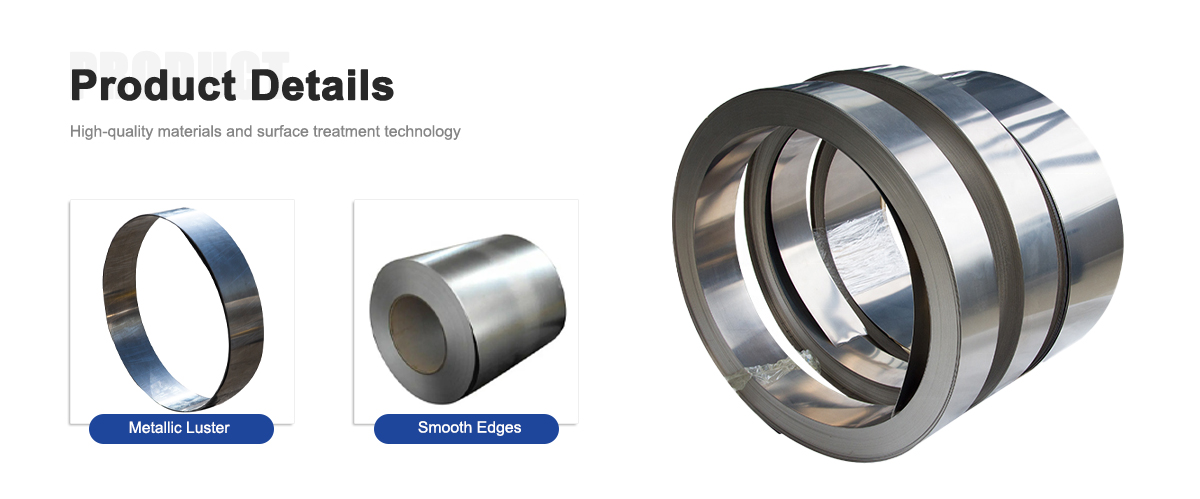

- Product Details

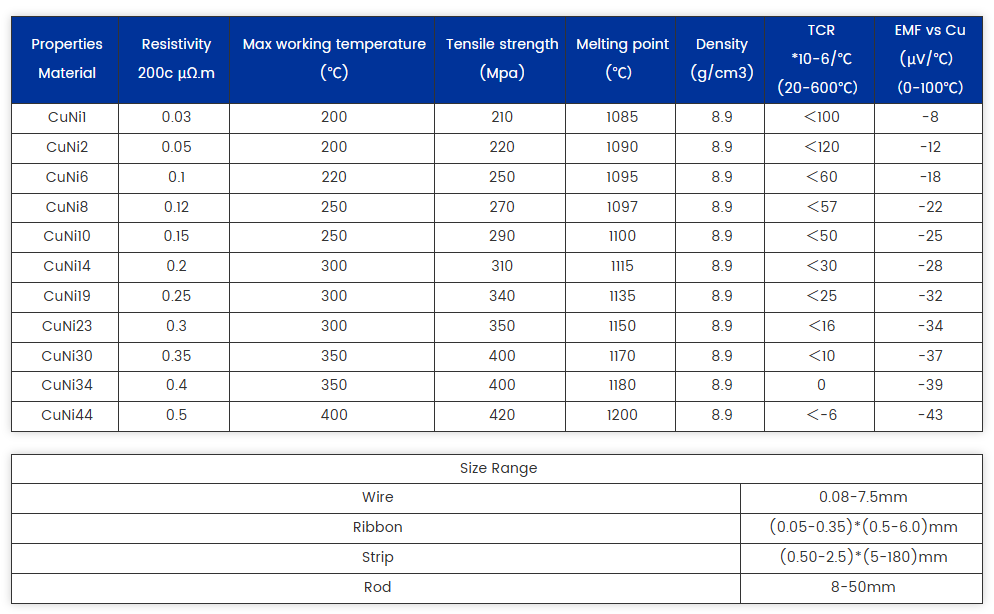

We’re pretty stoked about our Nickel Copper Alloy 400, or CuNi 34 as it’s known in the biz. This 0.5mm x 180mm soft MPA strip is one of our best sellers, and for good reason—it’s a total workhorse in industries that need materials to stand up to tough conditions. With 34% nickel and the rest mostly copper, this alloy brings a killer combo of corrosion resistance, low electrical resistance, and heat tolerance that makes it a go-to for all sorts of applications.

Let’s talk about why this alloy shines. First off, it laughs in the face of corrosion, especially in harsh environments like seawater. That’s why it’s a favorite in marine setups—think desalination plants, shipbuilding, or offshore oil rigs. We’ve seen it used in everything from propeller shafts to seawater piping systems, and it just keeps performing. It’s also got this awesome low electrical resistance, which makes it perfect for things like thermal overload relays and low-resistance circuit breakers. Plus, it’s super easy to process and weld, so manufacturers love it for making complex parts without breaking a sweat.

The industry’s been buzzing about copper-nickel alloys lately, and CuNi34 is riding that wave. The global market for these alloys is growing fast—think a CAGR of around 5.9% through 2030, driven by demand in marine, renewable energy, and electronics sectors. With the push for desalination plants to tackle water scarcity and the boom in offshore energy projects, CuNi34’s corrosion resistance and durability are in high demand. We’re also seeing more interest in renewable energy applications, like geothermal plants and wind turbines, where this alloy’s ability to handle extreme conditions really pays off.

What sets our CuNi34 apart is its balance. It’s got enough nickel to boost strength and corrosion resistance but keeps things cost-effective compared to higher-nickel alloys. Cold-work it, and you can crank up its tensile strength even more—around 400 MPa in its soft state but way higher when processed. It’s also a champ at handling temperatures up to 600°C in some cases, which is why it’s a staple in heat exchangers and superheaters.

We’re not just resting on our laurels, though. The industry’s moving toward sustainable production, and we’re on board, exploring ways to recycle nickel alloys and cut down on our carbon footprint. Innovations like seamless extrusion for better pipe quality are also keeping us ahead of the curve. Sure, raw material prices can be a rollercoaster, but CuNi34’s long lifespan and low maintenance costs make it a smart pick for companies looking to save in the long run.

At the end of the day, our Nickel Copper Alloy 400 is all about reliability and versatility. Whether it’s powering electrical systems, surviving salty seas, or keeping things cool in high-heat setups, this alloy’s got your back. It’s no wonder it’s a bestseller—we’re proud to supply it to industries that need materials they can trust.

When it comes to high-performance alloys, Nickel Copper Alloy 400 (CuNi34) stands out as a top choice across industries. Its 0.5mmx180mm soft MPA variant is especially popular for precision applications, and here’s why.

First, corrosion resistance is unmatched—ideal for marine, chemical, and oil & gas sectors. Unlike stainless steel, it handles chlorides and acids effortlessly. Plus, its non-magnetic properties make it perfect for electronics and submarine cables.

Then there’s fabrication ease. Whether welding, bending, or machining, Alloy 400 adapts without losing integrity. And with thermal/electrical conductivity close to pure copper, it’s a go-to for heat exchangers and electrical components.

Market trends show rising demand in renewable energy and aerospace, where durability meets lightweight needs. Competitors like Alloy 200 or SS316 can’t match its balance of cost, performance, and versatility.

Bottom line? If you need a reliable, long-lasting material, Alloy 400 isn’t just an option—it’s the best-selling solution for a reason.

Copper nickel CuNi34 alloy has low electric resisitance, which have 34% nickel and balance is copper, it is good heat-resistant and corrosion-resistant, easy to be processed and lead welded. It is used to make the key components in the thermal overload relay, low resistance thermal circuit breaker, and the electrical appliances. It is also an important material for electrical heating cable.

CuNi34 Copper Nickel alloy resistance heating strip.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ:

What is Nickel Copper Alloy 400 (CuNi34)?

It’s a nickel-copper alloy with about 34% nickel and the rest copper, known for its low electrical resistance, corrosion resistance, and heat tolerance. It’s often called Monel 400 in some contexts.

What are the main applications for CuNi34?

We use it in thermal overload relays, low-resistance circuit breakers, electrical heating cables, and marine components like pumps and valves due to its corrosion resistance.

How does CuNi34 perform in seawater environments?

It’s a champ in seawater! Its high corrosion resistance makes it ideal for marine applications like shipbuilding, desalination plants, and offshore oil and gas systems.

Can CuNi34 be welded easily?

Yep, it’s easy to weld and process, which makes it a go-to for manufacturing complex components without much hassle.

What’s the strength like for CuNi34?

It’s got solid strength, especially when cold-worked, with a tensile strength around 400 MPa in its soft state, and it stays tough across a wide range of temperatures.

Is CuNi34 suitable for high-temperature applications?

Absolutely, it handles temperatures up to 500-600°C for certain applications, making it great for heat exchangers and high-pressure superheaters.

How does CuNi34 compare to other copper-nickel alloys?

Compared to 90-10 or 70-30 Cu-Ni alloys, CuNi34 has higher nickel content, giving it better corrosion resistance but slightly lower strength unless cold-worked.

What industries rely on CuNi34 the most?

Marine, electrical, chemical processing, and renewable energy sectors love it for its reliability in tough environments like seawater piping and geothermal plants.

-

Cheap Price 8.9g/cm3 Hardness Range of 80-120HV With Low Resistivity CuNi Alloy Strip

Enquire Now -

Low Resistivity With High Temperature Customized CuNi Alloy Strip For Sale

Enquire Now -

CuNi Alloy NC010(CuNi6)The Optimal Solution for High-Temperature and High-Pressure Applications

Enquire Now -

8.94 G/cm3 CuNi Alloy NC005(CuNi2) with High Tensile Strength and Hardness

Enquire Now