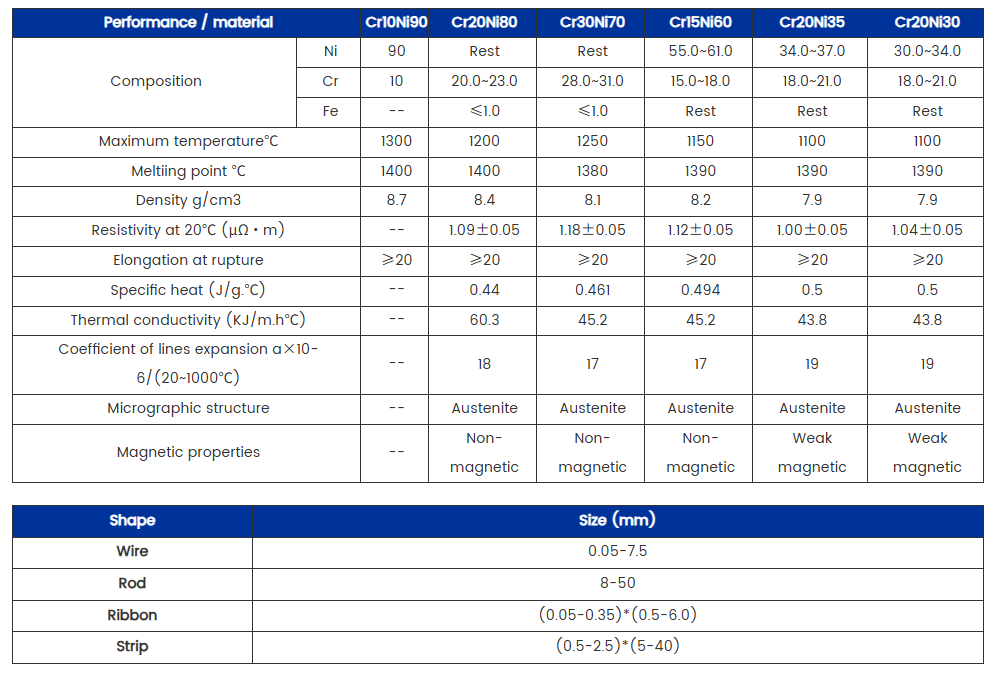

1350-1400°C Melting Point Alloy Bar for High Pressure and Stress Applications

- Product Details

Our alloy bar with a 1350-1400°C melting point is a powerhouse for OEMs tackling high-pressure and high-stress applications in extreme environments. Likely a nickel-chromium-based alloy like Inconel 600 (60-80% nickel, 15-20% chromium), this bar delivers the strength, thermal stability, and corrosion resistance needed to perform where lesser materials would fail.

This alloy’s high melting point (1350-1400°C) and operating temperature up to 1000-1100°C make it a champ for extreme heat applications, like aerospace turbine blades, industrial furnace components, and chemical processing reactors. Its tensile strength (600-900 MPa) and excellent creep resistance ensure it holds up under intense pressure and mechanical stress, making it ideal for high-pressure vessels and gas turbines. The protective oxide layer formed by its chromium content provides top-notch resistance to oxidation and corrosion in harsh, oxidizing environments (though sulfur-rich conditions should be avoided).

With 20-30% elongation, this bar is ductile enough to be formed into complex shapes, whether you’re crafting intricate aerospace parts or robust reactor components. Its weldability makes it easy to integrate into custom designs, though machining requires some care due to its hardness. The alloy’s resistivity (~1.0-1.3 µΩ·m) also supports applications like heating elements or resistors, while its thermal conductivity (10-15 W/m·K) ensures efficient heat dissipation in high-temperature systems.

The nickel alloy market is thriving, with a CAGR of about 5-6%, driven by demand in aerospace, power generation, and chemical processing. As industries push for components that can handle extreme conditions, this alloy bar’s combination of strength, thermal stability, and corrosion resistance makes it a top pick. Compared to FeCrAl alloys, it offers better ductility and corrosion resistance in oxidizing environments; compared to CuNi44, it handles much higher temperatures.

We produce this alloy bar with strict quality controls to ensure consistent strength, resistivity, and thermal properties. Our process supports customization for OEM needs, and we’re exploring sustainable practices like nickel alloy recycling to keep our footprint light. While raw material prices can vary, the durability and low maintenance of this alloy make it a cost-effective choice for high-stakes applications.

In short, our 1350-1400°C melting point alloy bar is your trusted solution for high-pressure and high-stress environments. Whether you’re building turbine blades, reactors, or furnace components, it delivers the strength, heat resistance, and reliability to get the job done right.

Product Description:

The NiCr Alloy is available in different grades and strand numbers, including Ni60Cr23/Inconel601/UNS N06601/610H and 7, 19, 37... strands. This alloy is a great choice for applications that require excellent resistance to oxidation and scaling, making it ideal for use in high-temperature environments. It is also known for its outstanding resistance to corrosion and can withstand harsh chemicals and acids.

The NiCr Alloy is commonly used in various industries such as aerospace, automotive, and chemical processing. It is a popular choice for high-temperature applications such as gas turbines, industrial furnaces, and heat exchangers. This alloy is also used in electrical heating elements, thermocouples, and resistance wires.

When it comes to trade terms, the NiCr Alloy is available in FOB, EXW, and CIF. This means that customers have the option to choose the most suitable trade term that will work for their business needs. Additionally, the NiCr Alloy is made of copper and copper alloys, which gives it excellent electrical conductivity and resistance to corrosion.

In conclusion, the NiCr Alloy is an excellent choice for applications that require high strength, durability, and resistance to extreme temperatures and harsh environments. It is a versatile material that is widely used in various industries and is available in different grades and strand numbers. With its excellent mechanical properties and outstanding resistance to oxidation and scaling, the NiCr Alloy is a reliable and cost-effective solution for many applications.

For more details, pls directly contact us.

Applications:

One potential use for this alloy is in the construction of copper and copper alloy products. Its unique properties make it an excellent choice for use in electrical wiring and other applications where conductivity and durability are important. Additionally, NiCr Alloy can be used as a component in alloy steel metal, improving the strength and durability of the final product.

Another potential use for NiCr Alloy is in the production of Inconel nickel alloy. This high-performance alloy is known for its resistance to corrosion, high-temperature strength, and excellent mechanical properties. NiCr Alloy can be used as a key component in the production of Inconel nickel alloy, ensuring that the final product meets the high standards of performance and durability that are expected from this material.

Overall, if you are looking for a reliable and versatile alloy product, you should consider DLX's NiCr Alloy. With its impressive thermal expansion coefficient, high elongation rating, and excellent performance in a range of applications, this alloy is sure to meet your needs. Plus, with a free sample available, it's easy to try it out for yourself and see the benefits firsthand.

Model No: NCHW-1

Grade: Ni60Cr23/Inconel601/UNS N06601/610H

Customization:

DLX offers product customization services for our NiCr Alloy, an Inconel Nickel Alloy that is widely used in the production of hard metal alloys and copper based alloys. Our NiCr Alloy has a melting range of 1320-1370 °C and a melting point of 1350-1400°C. It can be treated through annealing and cold drawing processes to achieve desired properties. Our NiCr Alloy has a thermal expansion coefficient of 13.5 X 10-6/K and is available in various strand numbers including 7, 19, and 37. Our NiCr Alloy is manufactured in China and our team can work with you to create a customized product to meet your specific needs.

Support and Services:

The NiCr Alloy product is backed by our expert Product Technical Support team, who are available to provide you with technical assistance and advice on all aspects of the product including its properties, applications, and performance. Our team has extensive experience in the field and can help you with any questions you may have.

In addition to our technical support, we also offer a range of services to ensure that you get the most out of your NiCr Alloy product. These services include:

Custom alloy development

Material testing and analysis

Product design and engineering

Material selection and sourcing

Manufacturing and fabrication

Quality control and assurance

Product performance monitoring and evaluation

Our goal is to provide you with high-quality products and services that meet your specific needs and requirements. Contact us today to learn more about our NiCr Alloy product and how we can help you achieve your goals.

Packing and Shipping:

Product Packaging:

The NiCr Alloy product will be carefully packed in a sturdy cardboard box to prevent any damage during shipping.

The product will be wrapped in protective material to avoid scratches and other damages.

The packaging will also include a packing slip and instructions for use.

Shipping:

The NiCr Alloy product will be shipped via a reputable courier service.

The shipping cost will be included in the product price.

The estimated delivery time will depend on the destination and shipping method chosen.

Tracking information will be provided once the product has been shipped.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What is the alloy bar with a 1350-1400°C melting point?

It’s likely a nickel-chromium-based alloy (e.g., Inconel 600 or similar), with 60-80% nickel and 15-20% chromium, designed for high-temperature, high-pressure, and high-stress applications.

What are its primary applications?

It’s used in aerospace turbine components, industrial furnace parts, chemical processing equipment, and high-pressure vessels due to its strength and thermal stability.

How does it perform under high pressure and stress?

With tensile strength of 600-900 MPa and excellent creep resistance, it maintains structural integrity under high pressure and mechanical stress at elevated temperatures.

How does it handle corrosive environments?

It forms a protective oxide layer, offering excellent resistance to oxidation and corrosion in high-temperature, oxidizing, and chemical environments (avoid sulfur-rich conditions).

How does its melting point compare to other alloys?

Its 1350-1400°C melting point is higher than CuNi44 (1280-1300°C) but similar to FeCrAl (1400-1500°C), making it suitable for extreme heat applications.

Can it withstand high temperatures?

Yes, it operates reliably up to 1000-1100°C, ideal for applications like gas turbine blades and heat exchangers.

Which industries use this alloy bar?

Aerospace, chemical processing, power generation, and industrial manufacturing rely on it for high-temperature, high-pressure components.

Is it easy to process for manufacturing?

Its good ductility and weldability allow forming and joining into complex shapes, though machining requires care due to its hardness.

-

Corrosion-Resistant NiCr Alloy with High Thermal Conductivity and Precision Electrical Properties

Enquire Now -

Hot Sale OEM Melting Range From 1320°C To 1370 °C Nichrome Alloy Bar Material

Enquire Now -

New Hot Nickel Aluminum Bronze Bar Nickel Alloy B3 Round Bar/Rod For Sale

Enquire Now -

Cold Drawing Treatment Copper Bar And Copper Alloys with Ni-Cr Conductor Material

Enquire Now