Ni-Cr Conductor Material Copper Alloy Bar with Annealed Treatment

- Product Details

Our annealed copper alloy bar and NiCr conductor material are a killer combo for OEMs who need materials that balance top-notch conductivity with high-temperature durability. Whether you’re crafting electrical systems or heating components, these materials bring the performance, flexibility, and reliability to take your manufacturing to the next level.

Let’s kick things off with the annealed copper alloy bar. The annealing process works wonders, softening the alloy (typically copper with traces of tin or zinc) to boost ductility and make it super easy to form into precise shapes like busbars, connectors, or wiring. With a low resistivity of 0.02-0.05 µΩ·m, it’s a conductivity champ, ensuring efficient current flow for electrical applications. The tensile strength of 250-350 MPa and hardness of 50-80 HV give it just enough toughness for moderate-stress environments, while the smooth surface from annealing makes it ready for high-quality finishes. While it’s not the best in corrosive settings like seawater, its high thermal conductivity (150-350 W/m·K) and formability make it a go-to for electrical OEMs.

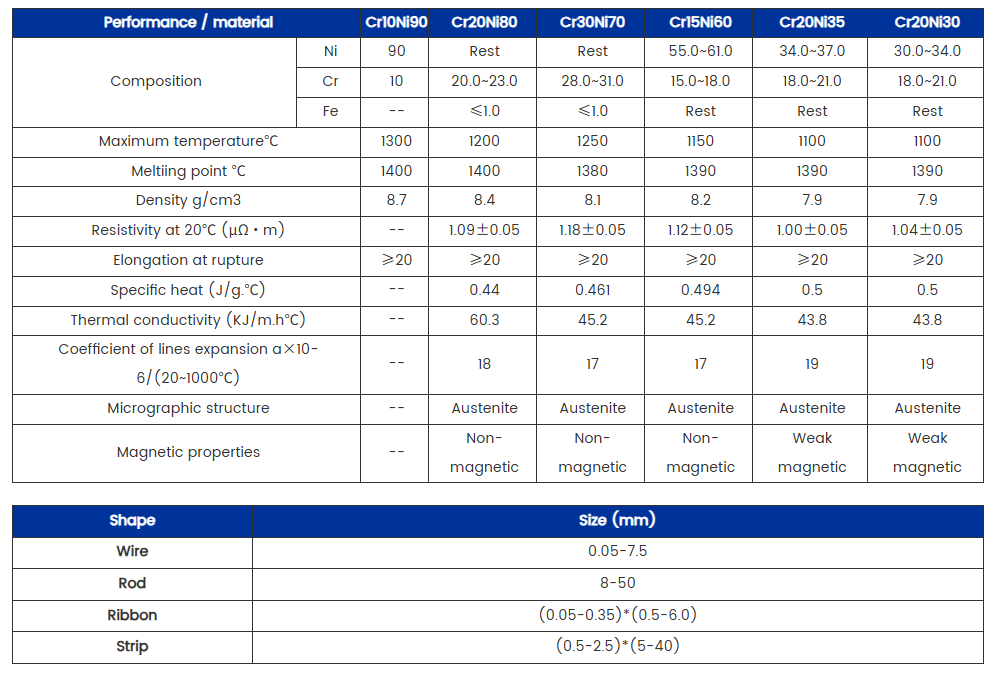

Then there’s our NiCr conductor material, typically 60-80% nickel and 15-20% chromium, built for heat and precision. With a high resistivity of 1.0-1.5 µΩ·m and a low temperature coefficient of resistance (~100 ppm/°C), it’s perfect for heating elements in toasters, ovens, and industrial furnaces, as well as precision resistors. It thrives at temperatures up to 1200°C, thanks to a protective chromium oxide layer that fights off oxidation and corrosion in oxidizing environments (just keep it away from sulfur-heavy settings). Its tensile strength (600-800 MPa) and hardness (180-220 HV) ensure durability, while its ductility allows for forming into wires or custom shapes, though machining requires some care due to its hardness.

The market for these materials is red-hot, growing at about 5-6% annually, driven by demand in electrical, aerospace, and industrial sectors. Annealed copper alloys power energy-efficient electrical systems, while NiCr conductors dominate in heating and resistance applications. Compared to CuNi44, copper alloys offer superior conductivity for low-resistance needs, while NiCr excels in high-temperature stability and oxidation resistance.

We produce these materials with tight quality controls to ensure consistent conductivity, strength, and surface quality. The annealing process for our copper alloy bars ensures optimal formability, and our NiCr conductor is crafted for reliable performance in extreme conditions. We’re also exploring sustainable practices, like recycling, to keep our process eco-friendly. Despite fluctuating raw material prices, the durability and efficiency of these materials make them a cost-effective choice.

In a nutshell, our annealed copper alloy bar and NiCr conductor material are your go-to for high-performance OEM projects. From electrical connectors to industrial heating systems, they deliver the conductivity, durability, and customization you need to make your next project a success.

Product Description:

One of the standout features of our NiCr alloy product is its impressive melting range. With a range of 1320-1370°C, our NiCr alloy product is capable of withstanding high temperatures with ease. This makes it ideal for use in a variety of applications where high heat resistance is required, such as in the production of Aluminium Copper Alloy, Inconel Nickel Alloy, and Copper Alloy Casting.

In addition to its impressive melting range, our NiCr alloy product also boasts a high melting point of 1350-1400°C. This makes it an excellent choice for use in high-temperature environments, where other materials may break down or fail.

When you choose our NiCr alloy product, you can rest assured that you are getting a top-quality product that is built to last. We take great pride in the quality of our products, and we stand behind everything we sell.

Ordering is easy – simply place your order online and we will ship your product directly to you from our port in Shanghai, China. Our leading time is 5-20 days, depending on the order quantity, so you can get your hands on your new NiCr alloy product in no time.

So why wait? Order your NiCr alloy product today and experience the difference for yourself!

For more details, pls directly contact us.

Applications:

This Alloy Steel Coil is available in both Soft and Hard states, making it ideal for various applications. The Soft state is perfect for applications that require flexibility and ease of use, while the Hard state is ideal for applications that require high strength and durability. This makes it suitable for use in various industries like aerospace, automotive, electronics, and many more.

The DLX NiCr Alloy is a popular choice for applications that require Hard Metal Alloys due to its high resistance to corrosion and oxidation. It is widely used in the production of heating elements, electric resistance wires, and many other applications that require high-temperature resistance. The NiCr Alloy is also an excellent choice for use in gas turbine engines, where it provides exceptional strength and durability.

This product is available under the FOB, EXW, and CIF Trade Term. Additionally, customers can avail of a free sample to test the quality of the product before making a purchase. The DLX NiCr Alloy is a reliable and durable material that is perfect for a wide range of industrial applications.

Customization:

Product Customization Services for NiCr Alloy

Brand Name: DLX

Model Number: NiCr Alloy

Place of Origin: China

Thermal Expansion Coefficient: 13.5 X 10-6/K

Conductor Material: Ni-Cr

Treatment: Annealed, Cold Drawing

Model No: NCHW-1

Trade Term: FOB, EXW, CIF

Our NiCr Alloy products can be customized to meet your specific needs. We offer customization options for copper alloy plates, hard metal alloys, and other materials. Our expert team can work with you to create a product that meets your exact specifications, whether you need a specific size, shape, or treatment. Contact us today to learn more about our product customization services.

Support and Services:

Our NiCr Alloy product technical support team is available to assist you with any questions or issues you may have. Our team of experts can provide guidance on product selection, installation, and troubleshooting. We also offer a range of services including custom alloy design, material testing, and prototyping.

Our goal is to ensure that our customers are satisfied with their NiCr Alloy product and that it performs optimally for their specific application. We are committed to providing excellent customer service and support to help our customers achieve their goals.

Packing and Shipping:

Product Packaging:

The NiCr Alloy product will be packed in a sturdy cardboard box.

The product will be wrapped in bubble wrap to prevent any damage during shipping.

The box will be sealed with strong adhesive tape to ensure the product is secure.

The packaging will include a label with the product name, quantity, and any other important information.

Product Shipping:

The product will be shipped via a reputable courier service.

The shipping cost will be calculated based on the weight and destination of the package.

The customer will receive a tracking number so they can monitor the progress of their shipment.

The estimated delivery time will be communicated to the customer.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What is an annealed copper alloy bar?

It’s a copper-based alloy bar (e.g., with small amounts of elements like tin or zinc) softened through annealing, offering high conductivity (~0.02-0.05 µΩ·m) and improved ductility for electrical applications.

What is NiCr conductor material?

NiCr (nickel-chromium) conductor material, typically 60-80% nickel and 15-20% chromium, has high resistivity (~1.0-1.5 µΩ·m) and is used for heating elements and resistors due to its thermal stability.

What are their primary applications?

Annealed copper alloy bars are used in electrical busbars, connectors, and wiring. NiCr conductors are used in heating elements (e.g., toasters, furnaces) and precision resistors.

How does annealing benefit the copper alloy bar?

Annealing reduces internal stresses, increases ductility, and enhances formability, making it easier to shape while maintaining good conductivity and strength (250-350 MPa).

How does NiCr perform in high-temperature environments?

NiCr alloys are stable up to 1200°C, forming a protective chromium oxide layer that resists oxidation and corrosion in high-temperature, oxidizing conditions (avoid sulfur-rich environments).

How do their electrical properties compare?

Copper alloy bars have low resistivity (~0.02-0.05 µΩ·m) for high-conductivity applications. NiCr’s high resistivity (~1.0-1.5 µΩ·m) suits heating and resistance applications.

Which industries use these materials?

Electrical, automotive, aerospace, and industrial manufacturing rely on copper alloys for conductivity and NiCr for heating and resistance components.

Are they easy to process for OEM applications?

Annealed copper alloys are highly ductile and machinable. NiCr is ductile and weldable but requires careful machining due to its hardness.

-

Corrosion-Resistant NiCr Alloy with High Thermal Conductivity and Precision Electrical Properties

Enquire Now -

Hot Sale OEM Melting Range From 1320°C To 1370 °C Nichrome Alloy Bar Material

Enquire Now -

New Hot Nickel Aluminum Bronze Bar Nickel Alloy B3 Round Bar/Rod For Sale

Enquire Now -

Cold Drawing Treatment Copper Bar And Copper Alloys with Ni-Cr Conductor Material

Enquire Now