Nichrome Alloy The Dependable Material for Industrial Heating Requirements

- Product Details

Look, we get it—industrial heating is no joke. You need a material that can take the heat (literally) and keep things running smoothly without cracking under pressure. That’s where Alloy 52 comes in, and we’re proud to say it’s one of the most reliable materials we offer for those tough industrial heating requirements.

So, what’s the deal with Alloy 52? It’s a nickel-iron alloy—about 50.5% nickel, 48% iron, with a sprinkle of other elements to keep it stable. The magic here is its low thermal expansion. This stuff doesn’t budge much when the temperature climbs, making it perfect for applications where precision is everything, like glass-to-metal seals in electronic tubes or automotive lamps. It’s like the cool-headed engineer who stays calm when everyone else is sweating.

Why do industries love it? For starters, it’s a champ at matching the thermal expansion of soft glass and ceramics. That means you get tight, reliable seals that don’t crack or leak, even when things heat up to around 525°C. Plus, it’s got great corrosion resistance, so it holds up in harsh environments where other materials might throw in the towel. And let’s not forget its magnetic properties—Alloy 52 is a go-to for magnetic reed switches in telecom and electronics. It’s like the Swiss Army knife of alloys.

From a manufacturing standpoint, Alloy 52 is a dream to work with. It’s machinable, so we can shape it into rods—like the 45mm diameter, 1-meter-long ones you might be eyeing—without much hassle. Whether it’s for aerospace components, hermetic seals, or high-precision electronics, this alloy gets the job done. We’ve seen it used in everything from tiny reed switches to critical parts in satellite systems. Talk about versatility.

Now, let’s talk trends. The push for smaller, more efficient electronics is driving demand for materials like Alloy 52. As industries like telecom and automotive lean into miniaturization and high-reliability components, alloys with low thermal expansion are becoming non-negotiable. Add to that the growing aerospace sector, where precision and durability are everything, and Alloy 52 is riding a wave of relevance. We’re also seeing more companies prioritize corrosion-resistant materials to cut down on maintenance costs, and guess what? Alloy 52 checks that box too.

We’re not saying it’s perfect for every job—materials like Kovar or Alloy 42 have their own strengths—but for applications where you need a balance of low expansion, magnetic properties, and workability, Alloy 52 is tough to beat. It’s the kind of material that makes our customers’ lives easier, and honestly, that’s what we’re all about. Whether you’re building the next big thing in electronics or need a reliable rod for a niche application, Alloy 52 has your back.

For more details, pls directly contact us.

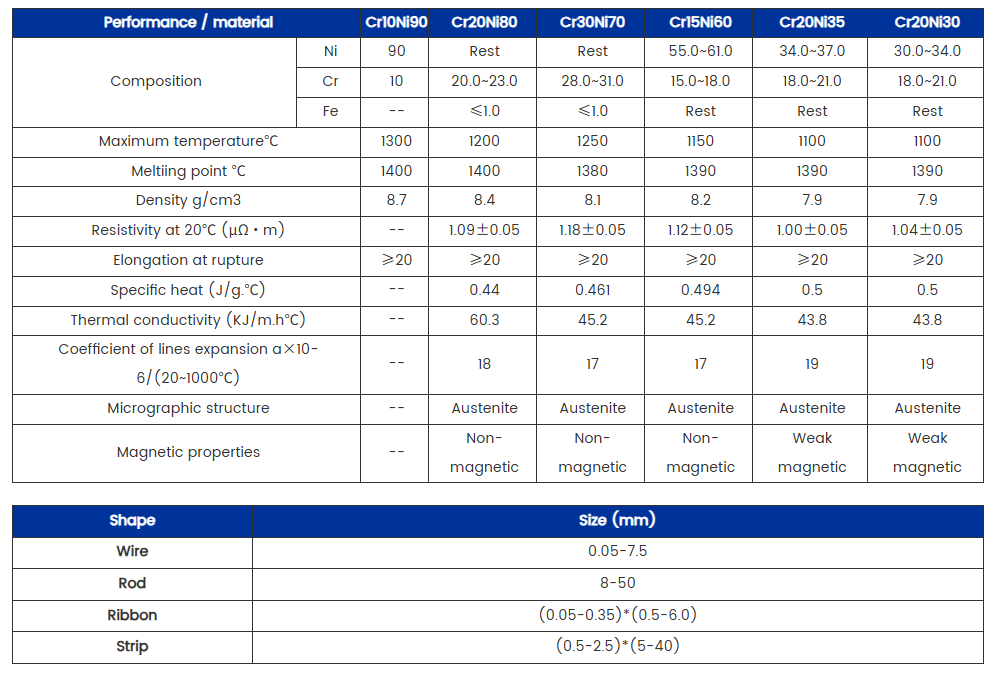

Product Description:

One of the key benefits of Nichrome wire is its high tensile strength, which ranges from 400-500 MPa. This means that it can withstand a significant amount of stress without breaking or deforming, making it ideal for use in heating elements and other applications that require durability and reliability.

The chemical composition of Nichrome wire is primarily made up of Ni-Cr-Fe, which gives it its unique properties. The nickel content helps to provide resistance to corrosion, while the chromium content gives it high heat resistance and oxidation resistance. The iron content helps to provide strength and stability to the wire.

Another important attribute of Nichrome wire is its thermal expansion, which ranges from 13-17 μm/mK. This means that it can expand and contract with changes in temperature without breaking or becoming damaged. This is particularly important in heating applications where the wire is subjected to high temperatures and thermal cycling.

In addition to its high tensile strength and excellent chemical composition, Nichrome wire also has a high elongation of 20-30%. This means that it can stretch without breaking, which is important in heating applications where the wire is subjected to repeated stress and strain.

Finally, it is worth noting that Nichrome wire is non-magnetic in nature, which makes it ideal for use in applications where magnetic properties are undesirable. This can include everything from heating elements for industrial ovens and furnaces to electrical components for sensitive electronic devices.

In summary, if you are looking for a durable, reliable, and high-performance heating element, then Nichrome Alloy is an excellent choice. With its high tensile strength, excellent chemical composition, thermal expansion, elongation, and non-magnetic properties, it is well-suited to a wide range of industrial and commercial applications. Whether you are looking for heating elements for your laboratory, manufacturing facility, or commercial kitchen, Nichrome wire is a versatile and cost-effective solution that you can rely on.

Features:

Product Name: Nichrome Alloy

Applications: Heating Elements, Furnaces, Electrical Components

Electrical Resistivity: 1.1-1.2 μΩm

Corrosion Resistance: Excellent

Melting Point: 1400-1450°C

Forms: Wire,Strip, Rod

Applications:

The Nichrome product is non-magnetic and comes in various forms such as wire, sheet, strip, rod, and tube. With a melting point of 1400-1450°C, this product is perfect for high-temperature applications. In addition, it has excellent corrosion resistance, making it a reliable choice for products that will be exposed to harsh environments. The thermal conductivity of Nichrome ranges from 15-20 W/mK, making it great for use in heating applications.

One of the most popular forms of the Nichrome product is Nichrome coil. This coil is used in a variety of products such as heating elements in ovens, toasters, and hair dryers. The coil is made of Nichrome wire which is known for its high resistance to corrosion and oxidation. The wire is also used in the production of heating elements for industrial furnaces and kilns.

Overall, Nichrome is a versatile product that can be used in a wide range of product application occasions and scenarios. Its non-magnetic properties, excellent corrosion resistance, and high melting point make it a reliable choice for high-temperature and harsh environments. DLX Alloy's Nichrome product is a great choice for those looking for a high-quality and reliable product.

Customization:

DLX alloy provides product customization services for Nichrome alloy, model number Nichrome. Our products are manufactured in China JiangSu and are certified with CE. The minimum order quantity is 5 and packaging details include spool package with carton box, coil package with polybag for resistance wire. Delivery time ranges from 5-21 days and payment terms accepted include L/C, T/T, Western Union, and MoneyGram. Our supply ability is 300 tons per month with a hardness of HV400-500 and thermal expansion of 13-17 μm/mK. Our Nichrome coil has excellent corrosion resistance and is available in forms such as wire, sheet, strip, rod, and tube. The elongation of our product is 20-30%. Our Nichrome coil is also known as Cr20Ni80.

Support and Services:

The Nichrome Alloy product is designed to provide high resistance and high temperature capabilities for use in applications such as heating elements, resistance wires, and electrical contacts.

Our technical support team is available to assist with any questions or concerns regarding the selection, installation, and maintenance of the Nichrome Alloy product.

In addition, we offer a range of services including custom alloy development, material testing, and failure analysis to ensure the highest level of performance and reliability for our customers.

Packing and Shipping:

Product Packaging:

The Nichrome Alloy product will be securely packed in a sturdy cardboard box to ensure safe transport. The box will be labeled with the product name and specifications for easy identification. Inside the box, the product will be further protected with bubble wrap or foam padding to prevent any damage during transit.

Shipping:

We offer worldwide shipping for the Nichrome Alloy product. The shipping cost and delivery time will depend on the destination and the shipping method selected at checkout. We have a variety of shipping options available to suit your needs, including standard, express, and expedited shipping.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What is Alloy 52 made of?

It’s a nickel-iron alloy with about 50.5% nickel and 48% iron, plus trace elements for stability.

What’s the main use of Alloy 52 rods?

They’re used for glass-to-metal seals in electronics, telecom, and automotive components.

Why choose Alloy 52 for sealing?

Its thermal expansion matches soft glass and ceramics, ensuring tight, reliable seals.

Can Alloy 52 handle high temperatures?

Yes, it performs well up to around 525°C without losing its properties.

Is Alloy 52 magnetic?

Yes, its high nickel content makes it suitable for magnetic applications like reed switches.

What industries use Alloy 52?

Electronics, aerospace, telecommunications, and automotive industries rely on it.

Can Alloy 52 be machined easily?

Absolutely, it’s known for good machinability, making it easy to shape into rods or other forms.

Where can I source Alloy 52 rods?

Suppliers like Ed Fagan or EFINEA offer Alloy 52 rods in various sizes, including custom cuts.

-

Corrosion-Resistant NiCr Alloy with High Thermal Conductivity and Precision Electrical Properties

Enquire Now -

Hot Sale OEM Melting Range From 1320°C To 1370 °C Nichrome Alloy Bar Material

Enquire Now -

New Hot Nickel Aluminum Bronze Bar Nickel Alloy B3 Round Bar/Rod For Sale

Enquire Now -

Cold Drawing Treatment Copper Bar And Copper Alloys with Ni-Cr Conductor Material

Enquire Now