NiCr Alloy Bar with 20-30% Elongation and Conductor Material

- Product Details

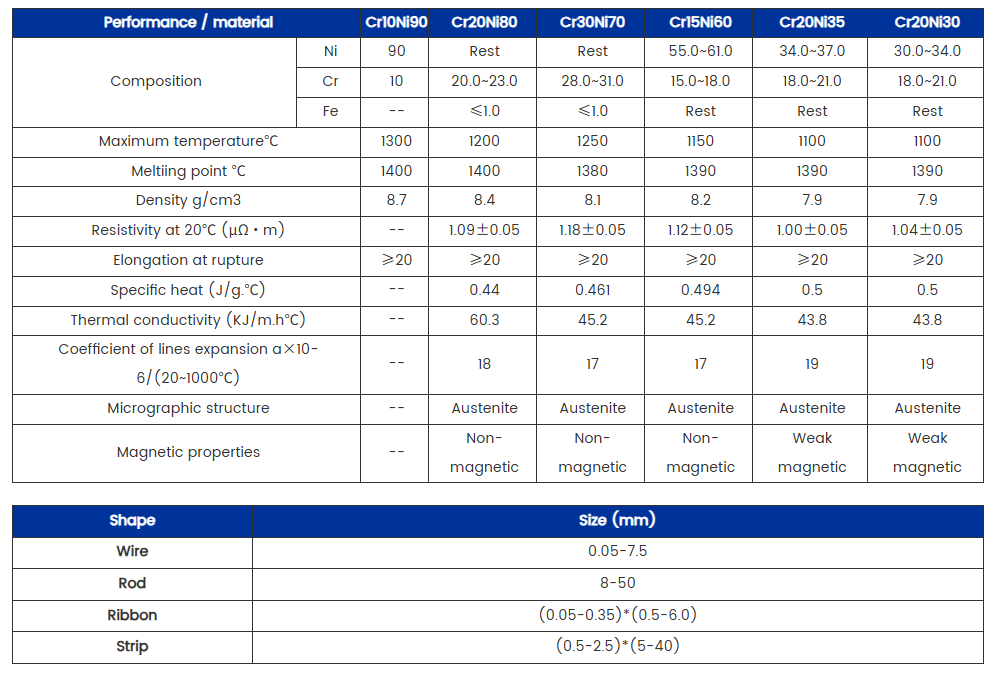

Our NiCr alloy bar, boasting 20-30% elongation and stellar conductor properties, is a hot pick for manufacturers who need a material that can handle heat, resist corrosion, and shape up easily. With a typical composition of 60-80% nickel and 15-20% chromium, this alloy is built for high-performance applications where reliability and precision are key.

The 20-30% elongation is a big deal—it means this bar is super ductile, letting you form it into wires, strips, or custom shapes without cracking. That makes it a dream for OEMs crafting heating elements for toasters, ovens, or industrial furnaces, as well as precision resistors and thermocouples. Its high resistivity (~1.0-1.5 µΩ·m) and low temperature coefficient of resistance (~100 ppm/°C) ensure stable performance, even when temperatures soar up to 1200°C. Plus, the chromium oxide layer it forms provides top-notch oxidation resistance, making it a champ in harsh, high-temperature environments (just steer clear of sulfur-heavy settings).

With a tensile strength of 600-800 MPa and hardness of 180-220 HV, this NiCr bar is tough enough for demanding applications like aerospace turbine components or automotive resistors. Its thermal conductivity (11-17 W/m·K) is solid for heat dissipation, keeping systems efficient. While it’s not as conductive as copper, its ability to handle extreme heat and resist corrosion makes it a go-to for applications where copper would falter.

The nickel-chromium alloy market is growing at a steady 5-6% annually, fueled by demand in electrical, aerospace, and industrial sectors. As industries push for energy-efficient heating systems and durable components, our NiCr bar’s combination of elongation, resistivity, and high-temperature stability makes it a standout. Compared to CuNi44, it offers superior heat resistance, and versus pure copper, it’s far better in corrosive, high-temperature conditions.

We produce this NiCr alloy bar with strict quality controls to ensure consistent resistivity, strength, and ductility. Its 20-30% elongation makes it a breeze to process, whether you’re drawing it into wires or welding it into custom components. We’re also exploring sustainable practices, like recycling nickel alloys, to keep our process eco-friendly. While raw material prices can be a bit of a rollercoaster, the long lifespan and low maintenance of this alloy make it a cost-effective choice.

In short, our NiCr alloy bar with 20-30% elongation is your trusted solution for high-performance conductive applications. From heating elements to precision resistors, it delivers the durability, formability, and heat resistance you need to make your project a success. Ready to shape the future of your manufacturing? This alloy’s got you covered.

Product Description:

The NiCr Alloy is commonly used in high-temperature applications due to its excellent resistance to oxidation and corrosion. It is also known for its high strength and durability, making it an ideal material for many industrial and commercial purposes. This alloy is especially useful in applications that require resistance to heat and pressure, such as in the aerospace and power generation industries.

The NiCr Alloy is a Copper Alloy Casting, which means that it is part of a group of alloys that contain copper as their primary component. Copper and Copper Alloys are known for their high thermal and electrical conductivity, making them ideal for use in electrical and electronic applications. They are also highly malleable and ductile, allowing for easy shaping and forming into complex shapes and designs.

Overall, the NiCr Alloy product is a reliable and high-quality material that is perfect for a wide range of industrial and commercial applications. With its excellent resistance to oxidation and corrosion, as well as its high strength and durability, this alloy is sure to provide outstanding performance and longevity in even the most demanding environments.

For more details, pls directly contact us.

Applications:

DLX NiCr Alloy is widely used in the electrical industry for its excellent conductivity and thermal stability. The product is used in the manufacturing of heating elements, resistors, and electric furnace elements. The Ni-Cr alloy is also used in the production of copper clad steel and copper-based alloys. The product's elongation properties of 20-30% make it suitable for applications that require flexibility and high strength.

The DLX NiCr Alloy is ideal for use in the construction industry for its ability to withstand harsh weather conditions and high temperatures. The product is used in the manufacturing of heating elements, thermocouples, and furnace parts. The Ni-Cr alloy is also used in the production of copper and copper alloys such as brass and bronze. These alloys are used in the production of electrical components, plumbing fixtures and decorative items.

The DLX NiCr Alloy is also widely used in the automotive industry for its excellent corrosion resistance and high strength. The product is used in the manufacturing of engine parts, exhaust systems, and brake systems. The Ni-Cr alloy is also used in the production of copper-based alloys such as beryllium copper and phosphor bronze. These alloys are used in the production of electrical contacts, springs, and bearings.

The DLX NiCr Alloy has a leading time of 5-20 days based on the order quantity. The product is available in different treatment options such as annealed and cold drawing to provide enhanced mechanical properties. The Ni-Cr alloy is an excellent alternative to copper and copper alloys due to its high strength, corrosion resistance, and thermal stability.

Customization:

Our product customization services are available for the DLX NiCr Alloy, originating from China with the model number NCHW-1. It is made of Ni-Cr alloy steel metal and is available with strand numbers of 7, 19, 37, etc. The grade of this product is Ni60Cr23/Inconel601/UNS N06601/610H, and it has a thermal expansion coefficient of 13.5 X 10-6/K.

Our customization services allow you to tailor the DLX NiCr Alloy to meet your specific requirements. Whether you need a different strand number or want to choose from other materials such as aluminium copper alloy or alloy steel metal, we are here to help. Contact us today to learn more about our product customization services.

Support and Services:

Our NiCr alloy product is designed to offer high temperature resistance and excellent corrosion resistance, making it ideal for use in a variety of industrial applications.

We offer comprehensive technical support and services to ensure that our customers get the most out of our NiCr alloy product. Our team of experts can provide guidance on product selection, installation, and maintenance to help you maximize the performance and lifespan of your NiCr alloy product.

In addition, we offer a range of value-added services, including custom fabrication and machining, to meet the unique needs of our customers. Our state-of-the-art facilities and experienced technicians enable us to deliver high-quality, precision-engineered components that meet even the most demanding specifications.

Whether you need technical support, custom fabrication, or other services, our team is committed to providing you with the highest level of service and support. Contact us today to learn more about how our NiCr alloy product and services can benefit your operation.

Packing and Shipping:

Product Packaging:

The NiCr Alloy product will be packaged in a sturdy cardboard box to ensure its safety during transport. Inside the box, the product will be wrapped in bubble wrap to prevent any damage during shipping. The box will be labeled with the product name, quantity, and any other relevant information for easy identification.

Shipping:

Our shipping service will ensure that the NiCr Alloy product is delivered to your doorstep in a timely and efficient manner. We offer a range of shipping options to suit your needs, including standard shipping, express shipping, and international shipping. Once your order has been processed, we will provide you with a tracking number so that you can follow the progress of your shipment. Please note that shipping times may vary depending on your location and the shipping option you choose.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What is a NiCr alloy bar with 20-30% elongation?

It’s a nickel-chromium alloy bar, typically with 60-80% nickel and 15-20% chromium, offering high resistivity (~1.0-1.5 µΩ·m), oxidation resistance, and 20-30% elongation for formability.

What are its primary applications?

It’s used in heating elements (e.g., toasters, industrial furnaces), precision resistors, thermocouples, and aerospace components due to its electrical and thermal properties.

What does 20-30% elongation mean?

The 20-30% elongation indicates high ductility, allowing the bar to be stretched or formed without breaking, ideal for shaping into wires, strips, or complex parts.

How does it perform in corrosive environments?

It forms a protective chromium oxide layer, providing excellent resistance to oxidation and corrosion in high-temperature, oxidizing environments (avoid sulfur-rich conditions).

How does its resistivity compare to other alloys?

Its resistivity (~1.0-1.5 µΩ·m) is higher than CuNi44 (~0.49 µΩ·m), making it better for heating elements but less conductive than copper (~0.017 µΩ·m).

Can it handle high temperatures?

Yes, it’s stable up to 1200°C, suitable for high-temperature applications like furnace elements and heating coils.

Which industries rely on this NiCr alloy bar?

Electrical, aerospace, automotive, and industrial manufacturing use it for heating elements, resistors, and high-temperature components.

Is it easy to process for manufacturing?

Its 20-30% elongation ensures good ductility for forming and drawing, and it’s weldable, though machining requires care due to its hardness.

-

Corrosion-Resistant NiCr Alloy with High Thermal Conductivity and Precision Electrical Properties

Enquire Now -

Hot Sale OEM Melting Range From 1320°C To 1370 °C Nichrome Alloy Bar Material

Enquire Now -

New Hot Nickel Aluminum Bronze Bar Nickel Alloy B3 Round Bar/Rod For Sale

Enquire Now -

Cold Drawing Treatment Copper Bar And Copper Alloys with Ni-Cr Conductor Material

Enquire Now