NiCr Alloy Rod 5-20 Days Leading Time with 20-30% Elongation

- Product Details

Our NiCr alloy rod, with 20-30% elongation and a fast 5-20 days lead time, is a premium solution for OEMs needing high-performance materials that can handle heat, corrosion, and precision demands. Likely a NiCr 80:20 alloy (60-80% nickel, 15-20% chromium), this rod combines ductility, electrical resistivity, and thermal stability to power a wide range of applications.

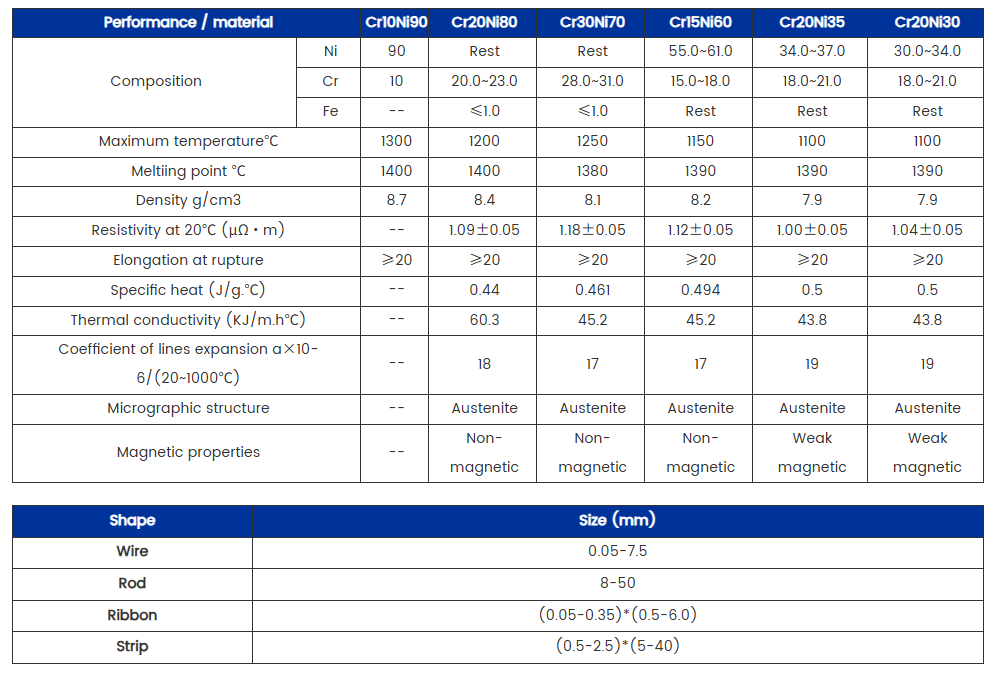

The 20-30% elongation is a key feature, giving this rod excellent ductility for forming into wires, strips, or custom components without cracking. This makes it a favorite for manufacturing heating elements for toasters, ovens, and industrial furnaces, as well as precision resistors and thermocouples. Its high resistivity (~1.0-1.5 µΩ·m) and low temperature coefficient of resistance (~100 ppm/°C) ensure stable performance in high-temperature environments up to 1200°C. The chromium oxide layer it forms provides outstanding oxidation and corrosion resistance, perfect for harsh, oxidizing conditions (though sulfur-rich environments should be avoided).

Product Description:

This NiCr Alloy is treated with annealing and cold drawing techniques that make it more durable and flexible. Annealing is a heat treatment process that reduces the hardness of the material and increases its ductility. On the other hand, cold drawing is a process of pulling the material through a die to reduce its diameter and improve its surface finish.

We offer free samples of the NiCr Alloy to our customers. This allows them to test the product before making a purchase. Our products are always available and ready to be shipped from our port in Shanghai, China.

The NiCr Alloy is an excellent alternative to copper and copper alloys. It is cheaper, more durable, and has better mechanical properties than copper. Additionally, this product is a suitable replacement for alloy steel coils and alloy steel metal. It has a higher temperature resistance and better corrosion resistance than alloy steel.

Our NiCr Alloy has a leading time of 5~20 days, depending on the order quantity. We ensure that our products are delivered on time and in good condition.

For more details, pls directly contact us.

Applications:

One of the primary applications of DLX NiCr Alloy is in the production of hard metal alloys. The product is perfect for producing hard metal alloys that are used in the manufacturing of cutting tools and abrasive materials. The product is also suitable for producing high-strength materials that can withstand extreme temperatures and harsh environments.

DLX NiCr Alloy is also useful in the production of aluminium copper alloy. The product is an excellent choice for producing aluminium copper alloys that have high strength and good corrosion resistance. Aluminium copper alloys are used in various applications, including automotive, aerospace, and electrical industries.

Inconel nickel alloy is another application where DLX NiCr Alloy is useful. The product is perfect for producing Inconel nickel alloys that have high strength, good corrosion resistance, and excellent heat resistance. Inconel nickel alloys are used in various applications, including the aerospace and chemical industries.

DLX NiCr Alloy is suitable for various occasions and scenarios, including FOB, EXW, and CIF. The product is available in different models, including NCHW-1. The product is of high quality, and customers can request a free sample to test its quality.

Customization:

Customize your DLX NiCr Alloy product to meet your specific needs. Our product customization services can adjust the following attributes:

Brand Name: DLX

Model Number: NiCr Alloy

Place of Origin: China

Leading Time: 5~20 Days As Per The Order Qty

Nickel Content: According To The Material

Thermal Expansion Coefficient: 13.5 X 10-6/K

Melting Range: 1320-1370 °C

Trade Term: FOB, EXW, CIF

Our NiCr Alloy product can be customized for use as Alloy Steel Coil, Hard Metal Alloys, or Copper Based Alloys. Contact us today to discuss your customization needs.

Support and Services:

Our NiCr Alloy product is backed by comprehensive technical support and services to ensure that you get the best performance out of our product. Our technical support team is available to answer any questions you may have about the product and its applications, as well as provide guidance on installation and maintenance.

In addition, we offer a range of services to help you get the most out of our NiCr Alloy product. Our services include customized solutions, testing and analysis, and expedited shipping options. We are committed to providing you with the highest level of customer service and support.

Packing and Shipping:

Product Packaging:

The NiCr Alloy product will be packed in a sturdy cardboard box.

The product will be wrapped in bubble wrap to ensure that it is protected during transit.

The box will be sealed with packing tape.

Shipping:

The NiCr Alloy product will be shipped through a reliable courier service.

The shipping cost will be calculated based on the destination and weight of the product.

The product will be shipped within 2-3 business days of receiving the order.

A tracking number will be provided to the customer once the product has been shipped.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What is the NiCr alloy rod with 20-30% elongation?

It’s a nickel-chromium alloy rod, typically 60-80% nickel and 15-20% chromium (e.g., NiCr 80:20), with high resistivity and 20-30% elongation for ductility, ideal for heating and resistance applications.

What does 20-30% elongation mean?

The 20-30% elongation indicates high ductility, allowing the rod to be stretched or formed into wires or components without breaking, perfect for manufacturing complex shapes.

What are its primary applications?

It’s used in heating elements (e.g., toasters, industrial furnaces), precision resistors, thermocouples, and aerospace components due to its thermal stability and electrical properties.

What does the 5-20 days lead time mean?

It refers to the time from order placement to delivery, typically 5-20 days, ensuring fast turnaround for OEM manufacturing needs, depending on supplier and order specifics.

How does it perform in corrosive environments?

It forms a protective chromium oxide layer, offering excellent resistance to oxidation and corrosion in high-temperature, oxidizing environments (avoid sulfur-rich conditions).

How does its resistivity compare?

Its resistivity (~1.0-1.5 µΩ·m) is higher than CuNi44 (~0.49 µΩ·m) but similar to FeCrAl (~1.2-1.5 µΩ·m), making it ideal for heating and resistance applications.

Which industries use this NiCr rod?

Electrical, aerospace, automotive, and industrial manufacturing rely on it for heating elements, resistors, and high-temperature components.

Is it easy to process for OEM applications?

Yes, its 20-30% elongation and good weldability make it easy to draw, form, and weld into custom components, though machining requires care due to its hardness.

-

Corrosion-Resistant NiCr Alloy with High Thermal Conductivity and Precision Electrical Properties

Enquire Now -

Hot Sale OEM Melting Range From 1320°C To 1370 °C Nichrome Alloy Bar Material

Enquire Now -

New Hot Nickel Aluminum Bronze Bar Nickel Alloy B3 Round Bar/Rod For Sale

Enquire Now -

Cold Drawing Treatment Copper Bar And Copper Alloys with Ni-Cr Conductor Material

Enquire Now